In the construction of modern storage facilities, steel structure warehouses have become one of the mainstream building forms due to…

Common architectural structure forms are divided into the following types: steel structure, prefabricated building, frame structure, suspension structure, arch structure, membrane structure, masonry structure, and brick-concrete structure.

Architectural Structure Forms

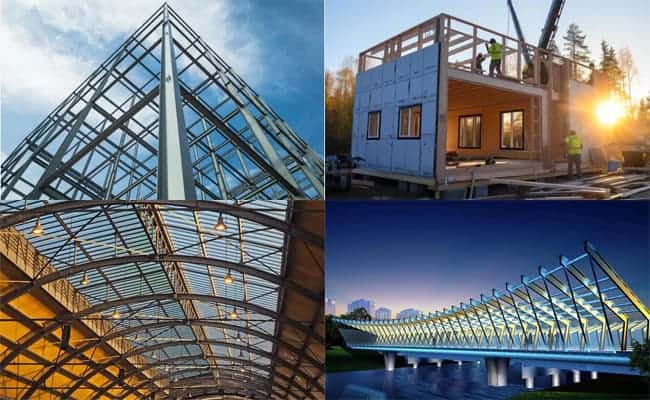

Steel Structure

A steel structure is mainly made of steel and is one of the main types of building structures. The structure primarily comprises steel beams, columns, trusses, and other components made of shaped steel and steel plates. It uses rust removal and anti-rust processes such as spray painting and galvanizing. Welds, bolts, or rivets usually connect each element or component.

Steel is characterized by high strength, lightweight, and rigidity, so it is particularly suitable for constructing large-span, ultra-high, and ultra-heavy buildings. It is widely used in large factories, stadiums, super high-rises, bridges, and other fields.

Types of steel structures:

Steel structures are one of the main types of architectural structures. Common steel structures include light, single-story, multi-high-rise, and large-span structures.

Light steel structure

A light steel structure is a structure that uses hot-rolled steel, welded steel, and high-frequency welded steel as the main stress-bearing components. Its types mainly include lightweight frames, portal frames, low-rise keels, and other structures. It has the characteristics of earthquake resistance, wind resistance, and durability.

Single-story steel structure

A single-layer steel structure is a steel structure with only one layer. It can adopt frame structures, support structures, etc. Each structural unit must form a stable spatial structure system. The spacing between supports of single-layer steel structure columns must be determined based on the longitudinal column spacing, stress conditions, and installation conditions of the building.

Multi-high-rise structure

According to the characteristics of lateral force-resistant structures, multi-high-rise steel structures are divided into megastructures, frame supports, and cylinder structures. Outrigger trusses or belt trusses can be installed to increase structural rigidity.

Large-span steel structure

The large-span steel structure has a transverse span of 60m, a concrete span of more than 30m, and a frame structure of more than 18m. The structural form includes large space structures such as grid structures, lattice shell structures, suspension structures, and various combined space structures. Its design must be determined based on a comprehensive analysis of the project’s plane shape, body shape, span, support conditions, load size, and building functions.

Prefabricated building

Prefabricated buildings refer to buildings that are assembled on the construction site using prefabricated components. The advantages of this kind of building are that it is fast to construct, less subject to climate conditions, saves labor, and improves construction quality.

Advantage:

(1) The components can be industrially produced in the factory and installed directly at the construction site, which is convenient and fast and can shorten the construction period.

(2) The components are mechanized in the factory, so product quality is more accessible to control effectively.

(3) The input of turnover materials and the rental cost of materials and tools is reduced.

(4) Reduce the amount of wet work at the construction site, which benefits environmental protection.

(5) Due to the reduced workload on the construction site, material waste can be reduced to a certain extent.

(6) The components are highly mechanized, which can significantly reduce the number of on-site construction personnel.

Shortcoming:

(1) Because the current relevant domestic design and acceptance specifications lag behind the development of construction technology, prefabricated buildings have more significant restrictions on the total height of the building and the floor height.

(2) The use of embedded parts, bolts, etc., in buildings has increased significantly.

(3) Due to mold restrictions and transportation (horizontal and vertical) restrictions in the factory production of components, the component size cannot be too large.

(4) The requirements for on-site vertical transportation machinery are relatively high, and larger hoisting machinery needs to be used.

(5) The components are prefabricated in the factory, and the prefabrication factory cannot be too far from the construction site.

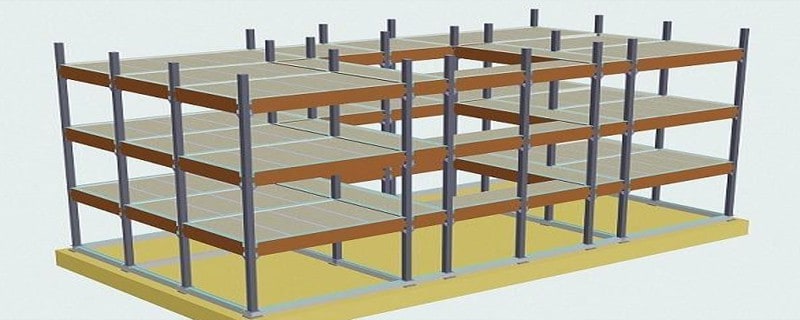

Framework

A frame structure is an architectural structure composed of beams and columns connected by rigid or hinged connections to form a load-bearing system. The frame of beams and columns jointly resists horizontal and vertical loads during the application process.

The walls are not load-bearing and only serve as enclosure and separation. They are generally built with prefabricated aerated concrete, expanded perlite, hollow or porous bricks, pumice, vermiculite, and other lightweight plates.

Advantage:

The most significant advantage of the frame structure is that the layout of the building space is flexible, and the randomness is relatively relaxed. Because the main stress-bearing components of the frame structure are columns and beams, and the walls are filled with lightweight materials, the layout of the building space is flexible.

The frame structure needs to be taller in terms of building height. The ones without brick-concrete are much higher. Similarly, different seismic intensities have different heights. The height shows that the frame is much stronger than the brick concrete regarding seismic resistance, and the floor height is not limited.

Shortcoming:

The disadvantages of the frame structure system are the stress concentration of the frame nodes is significant, the lateral stiffness of the frame structure is slight, and it is a flexible structural frame. Under the action of a strong earthquake, the horizontal displacement of the structure is large, which can easily cause non-structural severe damage;

The amount of steel and cement is large, the total number of components is large, the number of hoistings is high, the workload of joints is significant, and many processes waste manpower, and the construction is greatly affected by seasons and the environment;

Suspension structure

A load-bearing structure formed by flexible tension cables and their edge members. The material of the rope can be steel wire bundles, steel wire ropes, steel hinge wires, chains, round steel, and other wires with good tensile properties.

Planar suspension structure

A planar structure that mainly bears force in one plane is primarily used in suspension bridges and overhead pipelines. Divided according to structural form:

Single-layer suspension structure. It can be used as a flexible suspension bridge or as a roof. The structural rigidity is slight, and the deformation is large under variable loads. It is suitable to lay heavy roofs on the cables.

Reinforced single-layer suspension structure. Stiffening trusses (or strengthening beams) are suspended from several suspenders below the wires to enhance the rigidity of the structure.

Double-layer suspension structure. The curvature of the upper cable is opposite to that of the lower cable, and prestress is applied to the tensioned oblique web rod between them, so it has good stiffness.

Space suspension structure

A structure in a state of spatial stress is mainly used in long-span roof structures. Divided according to structural form:

Circular single-layer suspension structure.

The cables are arranged in a radial pattern for roofs with circular planes, and the entire roof forms a concave rotating surface. The outer end of each cable is fixed on the surrounding reinforced concrete ring beam, and the inner end is specified on the pull ring near the center of the circle. An umbrella-shaped suspension structure can be formed when columns are allowed at the circle’s center.

Circular double-layer suspension structure.

Its appearance is similar to the structure mentioned above, except that it has two layers of cables, upper and lower, so that different prestressed tie rods can enhance stiffness. The roof of the 94-meter-diameter competition hall of the Workers’ Stadium in Beijing, China, adopts this structural form. The pull ring near the circle’s center bears the circumferential pulling force and the pressure in the vertical direction.

Bidirectional orthogonal cable net structure.

It consists of two sets of mutually orthogonal cables. The concave group is the load-bearing cable, and the convex group is the stabilizing cable. The two groups of wires form a surface with negative Gaussian curvature. When prestressing is applied to one set of wires, the other set of cables also obtains the prestressing effect simultaneously.

Using prestress, the two sets of wires can always be in close contact under the roof load and get good stiffness. This cable net can be used for roofs with elliptical planes, rectangular planes, diamond planes, or other planes.

Arch structure

The arch structure is a curved or polygonal component that mainly bears axial pressure and is balanced by the thrust at both ends.

The arch structure consists of an arch ring and its supports. The supports can be made into piers that can withstand vertical force, horizontal thrust, and bending moment; walls, columns, or foundations can bear the sheer force, and tie rods can pay the horizontal thrust.

The arch ring mainly bears axial pressure, and the bending moment and shear force are smaller than those of beams with the same span. This can save materials, improve stiffness, and span larger spaces. It can be used as a bridge for auditoriums, exhibition halls, gymnasiums, train stations, aircraft hangars, etc. Long-span roof load-bearing structure. Using cheap building materials with high compressive strength and low tensile strength, such as bricks, stones, and concrete, is beneficial. Arches can be used in general load-bearing structures such as roofs, crane beams, lintels, retaining walls, bulk material warehouses, and load-bearing structures in underground buildings, bridges, dams, docks, etc.

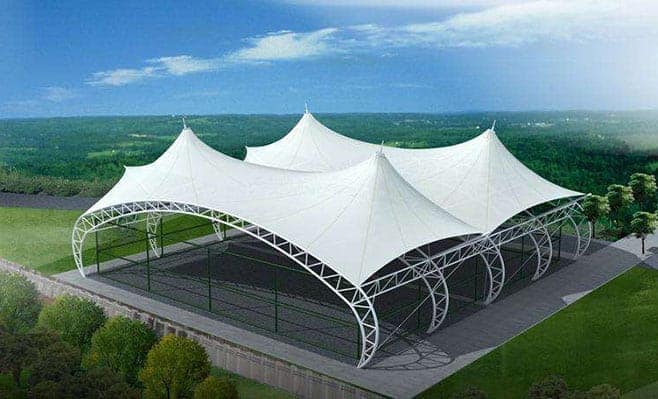

Membrane structure

Membrane structure is a new architectural structure developed in the mid-20th century. It is made of a variety of high-strength membrane materials (PVC or Teflon) and reinforced components (steel frame, steel column, or steel cable) to make the interior A spatial structure that generates particular pre-tensioned stress to form a specific spatial shape, serves as a covering structure, and can withstand specific external loads.

Membrane structures can be divided into two categories: inflatable membrane structures and tensile membrane structures.

Inflatable membrane structures rely on continuous inflating indoors to create a specific pressure difference between indoors and outdoors (generally between 10mm and 30mm water column).

The difference causes the roof membrane fabric to experience upward buoyancy, achieving a larger span. The tensile membrane structure is supported by columns and steel frames or tensioned by steel cables, and its shape is gorgeous and flexible.

Masonry structure

A structure built of brick, stone, or block masonry, also known as masonry. Since the compressive strength of masonry is high and the tensile strength is deficient, masonry structural members mainly bear axial or slight eccentric pressure but rarely tension or bending. Generally, walls, columns, and columns of civil and industrial buildings.

The foundation can be made of masonry. In buildings using reinforced concrete frames and other structures, brick walls are often used as enclosure structures, such as infill walls for frame structures.

The main advantages of masonry construction are:

- Easy to obtain local materials. Bricks are mainly fired from clay; the raw stone material is natural stone, and building blocks can be made from industrial waste ─ slag, which is conveniently sourced and cheap.

- Brick, stone, or block masonry has good fire resistance and durability.

- No formwork or special construction equipment is required for masonry construction. In cold areas, freezing masonry can be used in winter without special insulation.

- Brick and block walls can insulate and retain heat, making them better load-bearing and envelope structures.

The disadvantages of masonry construction are:

- Compared with steel and concrete, the strength of masonry is lower, so the cross-sectional size of the components is larger, the amount of material is more significant, and the weight is heavier.

- Masonry construction is manual, and the construction labor is immense.

- The tensile and shear strengths of masonry are very low, so the seismic resistance is poor, and its use is subject to certain restrictions; the compressive strength of bricks and stones cannot be fully exerted.

- Clay bricks must be made of clay, which takes up too much farmland in some areas and affects agricultural production.

Brick structure

Brick-concrete structure refers to a building where the vertical load-bearing walls, columns, etc., are made of bricks or blocks, and the horizontal load-bearing beams, floor slabs, roof panels, etc., are made of reinforced concrete structures.

In other words, the brick-concrete structure is a load-bearing structure with a small part of reinforced concrete and most of the brick walls. Brick-concrete structure is a type of hybrid structure.

It is a hybrid structural system comprising brick walls to bear load and reinforced concrete beams, columns, slabs, and other components. It suits buildings with small bay depths, small room areas, and multi-story or low-rise buildings. The load-bearing wall cannot be modified, while the frame structure can change most of the wall.

The layout of the walls of a brick-concrete structure building is as follows:

- The horizontal wall is load-bearing. Support floors with transverse walls parallel to the roofs. It is often used in small-bay buildings such as residences, dormitories, hotels, and office buildings with regular floor plans. The horizontal walls serve as partition and load-bearing walls, with a 3 to 4m spacing.

- The longitudinal wall is load-bearing. The eaves walls and longitudinal walls parallel to the eaves walls are used to support the floors. The bays can be arranged flexibly, but the stiffness of the building is poor, and large-area doors and windows cannot be opened on the facade.

- Mixed load-bearing of vertical and horizontal walls. Some use transverse walls, and some use longitudinal walls to support the floors. It is mainly used in buildings with complex planes and diverse internal space divisions.

- The brick wall and internal frame are mixed load-bearing. Internally, beams and columns are used instead of walls to bear the load, and the outer retaining wall also plays a load-bearing role. This arrangement allows for larger internal space and a flexible floor plan, but the building is not rigid enough. They are often used in large halls.

- The bottom layer is a reinforced concrete frame, and the upper part is a brick wall load-bearing structure. It is often used in buildings with shops on the ground floor or large spaces for public activities on the ground floor along the street, with residences, offices, or dormitories above.