In the construction of modern storage facilities, steel structure warehouses have become one of the mainstream building forms due to…

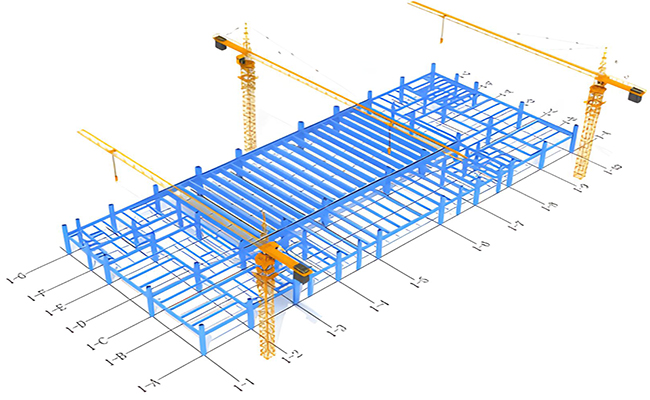

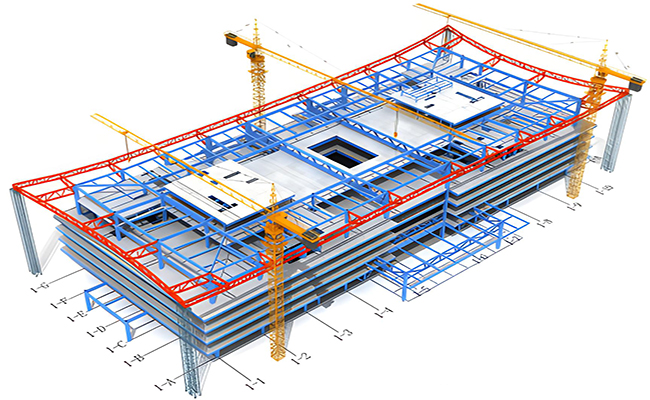

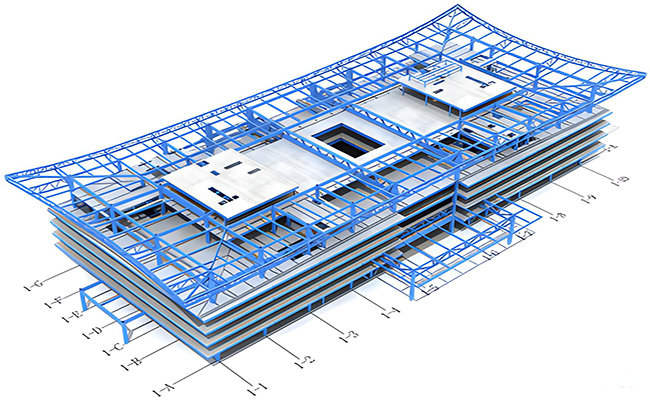

Steel frame structure installation is a crucial link in building construction. It involves multiple stages, from installing foundation anchor bolts and steel columns to the frame beams, floor decking, and concrete pouring, and then to installing roof trusses and edge trusses. The precise construction of each link directly affects the safety and stability of the building.

Steel frame structure installation

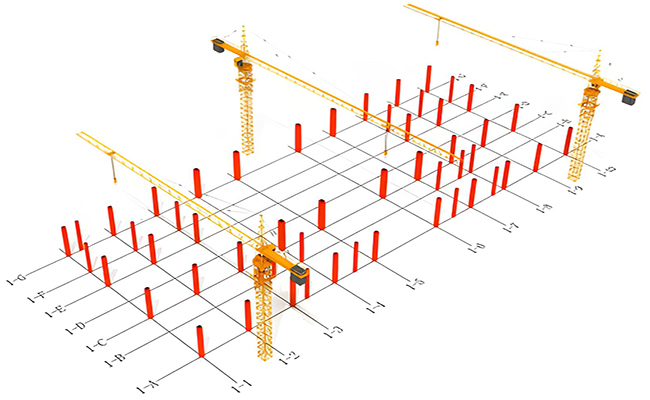

1. Anchor Bolts and Steel Columns Installation

The first step of steel frame structure installation – the installation of anchor bolts and steel columns, is the basis of the entire construction process. Through precise positioning, hoisting, and fixing, it can ensure the smooth progress of subsequent structural construction and lay a solid foundation for the safety and stability of the building.

Installation of embedded anchor bolts:

The embedded anchor bolts are essential for fixing steel columns in frame structures. Their accurate position directly affects the subsequent installation of steel columns and the building’s overall stability.

The main steps include:

Positioning measurement: According to the building drawings, use measuring tools such as theodolites and levels to mark the anchor bolt position on the foundation accurately.

Fixing anchor bolts: Fix the bolts through the template so that the anchor bolt axis coincides with the designed position to ensure verticality and flatness.

Pouring concrete: After the anchor bolts are positioned and fixed, pour concrete and vibrate to make it dense to ensure that the anchor bolts are stable and do not shift.

Steel column installation

The installation of steel columns is the initial forming stage of the steel frame structure.

The main steps are as follows:

Lifting operation: Use a tower crane to lift the steel column to the designed position, ensure lifting safety, and adopt reasonable lifting points and methods.

Column base fixing: After the steel column is in place, connect the column foot with the embedded anchor bolt, usually fixed by high-strength bolts, and correct the verticality one by one.

Calibration and acceptance: Use a total station or laser measuring instrument to check the verticality and axis position of the steel column to ensure that the error is within the allowable range.

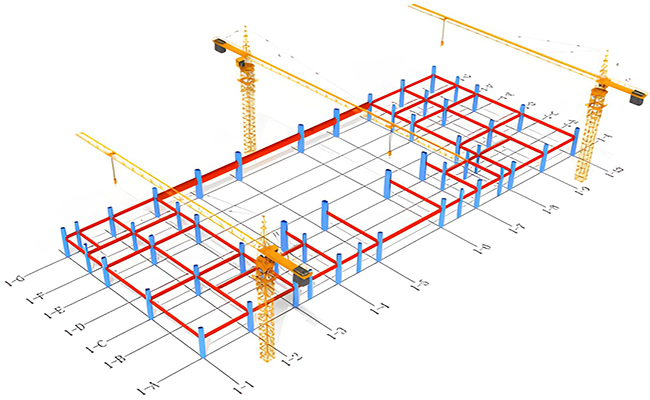

2. Steel frame structure installation: frame beam installation

Frame beam lifting is a key step in steel frame structure installation. It ensures the structure’s stability and creates favorable conditions for subsequent construction. Through precise lifting, connection, and correction, the frame beam connects the steel column into a whole, gradually forming a complete frame structure system.

Main beam installation

Lifting and positioning:

Use a tower or crane to lift the main beam to the designated position.

Ensure stability during lifting to prevent the frame beam from swinging and colliding with steel columns or other structures.

Temporary fixation:

Place the primary beam on the support position or connection node reserved by the steel column.

Use high-strength bolts or temporary supports for preliminary fixation to prevent displacement.

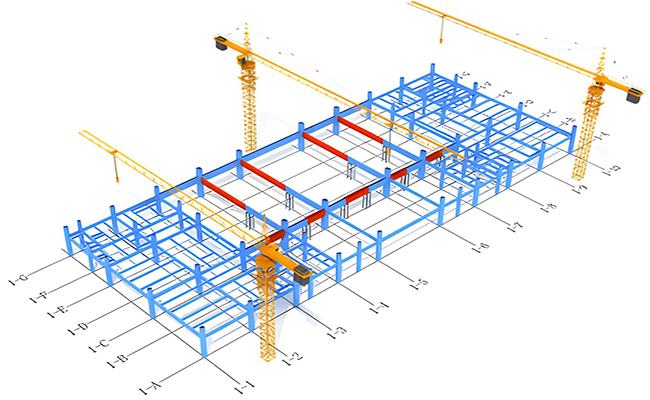

Secondary beam installation

The secondary beam mainly connects the frame beam to support the floor slab and wall further.

Lifting in place

The lifting of the secondary beam must be carried out after the frame beam is installed and fixed.

A tower crane lifts The secondary beam to the support position between the frame beams.

Temporary fixation

Place the secondary beam on the main beam at the preset node and use bolts or temporary clamps for preliminary fixation.

Ensure the secondary beam is firmly connected to the primary beam without displacement.

Position correction

Use measuring tools to check and adjust the secondary beam’s elevation, levelness, and spacing to ensure the steel frame installation meets the design requirements accurately.

Connection and fixation

The connection between the secondary beam and the primary beam is made of high-strength bolts, and the construction is carried out according to the requirements of the design drawings.

Installation sequence for Steel Beam:

First is the main beam, followed by the secondary beam. The main beam (frame beam) is the main load-bearing component. After installation and fixation, the secondary beam is installed.

First is the middle, then the two sides: Install from the middle of the building to the two sides in sequence to ensure structural stability.

Installation layer by layer: Install the frame beam and secondary beam step by step from bottom to top in the order of floors.

3. First-floor steel beam installation completed:

Complete first-floor structural system.

After the primary and secondary beams are connected, a stable first-floor floor frame system is formed, providing the first primary load-bearing system for the entire building. The main beam bears the main load, while the secondary beam disperses and transmits it to the main beam and steel column.

Provide a construction platform.

After the first-floor steel beam installation, some areas can be used as temporary construction platforms. This will provide a working basis for floor installation, temporary support, and upper structure hoisting.

Ensure structural stability

The steel beams and columns form a rigid connection through bolt connection and welding, fully guaranteeing the stability of the first-floor structural system and improving its ability to resist deformation and lateral displacement.

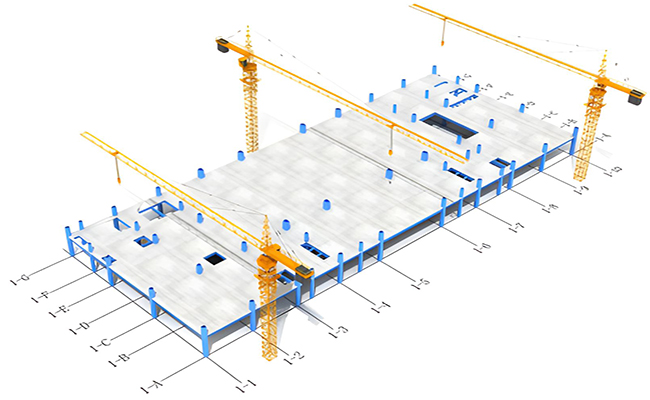

4. Laying floor deck and pouring concrete

The floor deck is an essential part of the steel frame floor. Corrugated steel plates are usually used as the concrete slab’s bottom formwork and stress-bearing steel bars.

Floor slab installation:

Floor deck hoisting

Use hoisting equipment (such as a crane) to lift the floor deck to the installation location.

During hoisting, ensure that the hoisting device is appropriately fixed on the slab to avoid damaging the plate.

Floor deck placement

Place the hoisted floor deck accurately to the predetermined position and firmly connect it to the support frame.

After installing each floor slab, use a level ruler and a plumb line to check its horizontality and verticality to ensure it meets the design requirements.

Floor slab connection and fixation

The floor slabs are connected, usually fixed by self-tapping screws, bolts, or welding to ensure that the joints are firm and not loose.

Check the connection points of the docking plate and the support system in detail to ensure that each connection point is tight and stable.

After installing the floor deck and laying the steel bars, pour concrete.

Concrete pouring

Use a pump truck or other pouring equipment to pour concrete evenly on the floor deck.

During the pouring process, pour in layers, and the thickness of each layer is controlled within 30cm to ensure that the concrete is evenly distributed.

Use a vibrator to vibrate the concrete to eliminate air gaps, ensure density, and prevent honeycomb surface phenomena.

After pouring, smooth the concrete surface in time to ensure the floor’s flatness meets the design requirements.

Cover and maintain the concrete to keep it moist. The maintenance cycle is generally 7-14 days to ensure the concrete strength meets the design requirements.

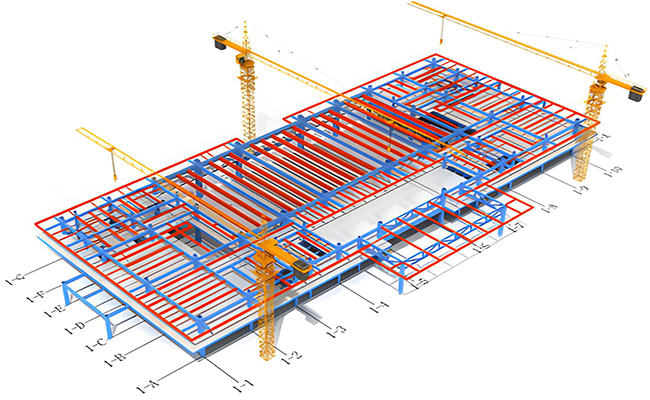

5. Install the second-floor steel columns and steel beams:

Compared with the installation of the first floor, although the overall steps and methods of installing the second-floor steel columns and steel beams are similar, due to differences in construction environment, component weight, installation height, and safety requirements, the installation of the second-floor steel frame is different in some details and precautions.

Main differences and precautions:

Construction environment differences

First-floor installation: The construction is close to the ground, the operator can quickly contact the components, and the construction speed is relatively fast.

Second-floor installation: As the height increases, the working environment becomes more complex, especially for hoisting equipment, worker operating space, and safety.

Safety protection

First-floor installation: The construction workers are close to the ground, and the safety protection is relatively simple, but they still need to wear essential safety equipment such as safety belts and helmets.

Second-floor installation: As the construction height increases, the safety risk of high-altitude operations also increases. Strict, high-altitude safety measures are required. All workers must wear safety belts, and each worker should fasten a safety rope and ensure that the temporary support facilities are firm. In addition, the crane’s stability must be ensured during the hoisting operation to avoid equipment tilting or loss of control.

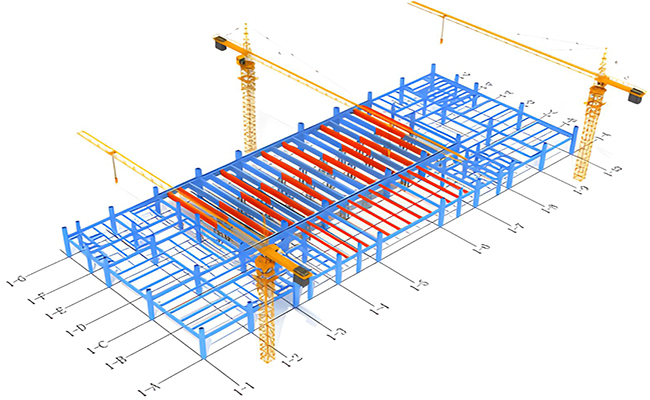

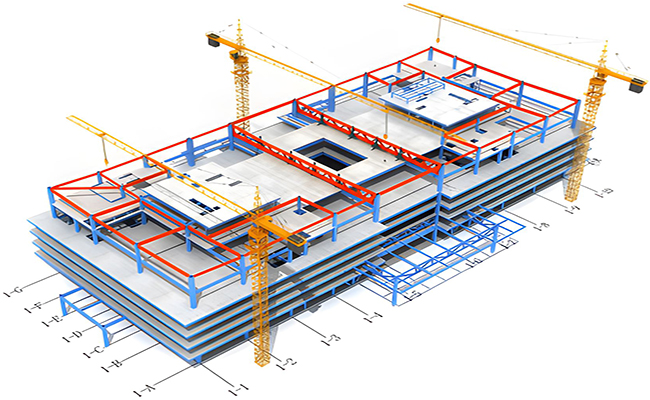

6. Installing roof trusses

Roof trusses are usually completed before the upper installation to ensure the stability and safety of the structure.

Hoisting roof trusses

Truss hoisting: Use a crane to lift the truss and ensure that the truss is in a horizontal state. During the installation process, the hoisting angle should be adjusted according to the actual situation on site.

Temporary fixation: After the truss is in place, use a temporary support device to fix the truss position to ensure its stability.

Precise docking and welding

Positioning docking: Ensure that each connection part of the truss is accurately docked with the connection point of the main frame of the steel structure. Usually, the connection method between the roof truss and the steel frame is bolt connection or welding.

Connection fixation: After confirming that the truss is accurately positioned, weld or bolt tighten according to the design requirements. It is necessary to ensure that all connection points meet the strength requirements.

7. Hoisting and positioning edge banding trusses

Hoisting edge banding trusses: Use hoisting equipment to hoist the edge banding trusses to the installation location. Since the edge banding trusses are located at the roof’s edge, special care must be taken during the hoisting process to avoid truss deviation or damage due to improper operation.

When hoisting, it usually starts from the center of the building, and one end is gradually hoisted into place.

Temporary fixation: After the initial hoisting, the edge banding trusses are firmly fixed in the predetermined position with a temporary support device. Ensure that the trusses do not deviate or tilt and can be stably supported.

Docking and fixing

Precise docking: After hoisting, ensure that the connection points between the edge truss and the roof truss are correctly docked, especially at the intersection of the edge and the main truss. At this time, you can use hoisting tools and measuring instruments to ensure that the trusses are docked correctly.

Connection and fixing: According to design requirements, use bolts, welding, or other connection methods to fix the edge truss to the main truss. Usually, the edge truss is bolted or welded.

Steel frame installation is a key link in steel structure construction. It involves complex processes, from component manufacturing and transportation to on-site assembly.

Correct and efficient installation ensures the structure’s safety and stability and directly affects the progress and cost control of the entire project.

Technical points of steel frame structure installation

Precision control

Steel frame structure installation is a delicate job, and any slight deviation may make subsequent processes difficult or even rework. Therefore, the installation accuracy must be strictly controlled, especially in multi-story or multi-span structures.

Safety guarantee

The construction site has many safety hazards, such as falling from height, mechanical injury, electric shock, etc. To this end, adequate protective measures must be taken, such as setting up safety nets, wearing personal protective equipment, and drawing cordons.

Environmental adaptation

The climatic conditions in different regions vary greatly, and extreme weather (such as typhoons, heavy rains, and blizzards) will affect steel frame installation progress and quality. Emergency plans should be formulated in advance, the construction period should be arranged reasonably, and the influence of adverse factors should be avoided as much as possible.

Coordination and cooperation

Steel frame installation involves multiple professional fields, including civil engineering, electromechanical, and decoration. All parties need to work closely together, keep information flowing, solve problems jointly, and ensure the smooth progress of the project.

Conclusion

Steel frame structure installation is a high-tech and comprehensive system project that is related to the overall performance and service life of the building.

Through careful planning, scientific management, and strict implementation of various technical standards, the installation efficiency and quality can be effectively improved, laying a solid foundation for subsequent decoration and other ancillary construction.