In the construction of modern storage facilities, steel structure warehouses have become one of the mainstream building forms due to…

Windows and doors for metal buildings play an essential role. They are a necessary part of the pre-engineered metal buildings. Their shape, size, proportion, arrangement, color all have a significant influence on the overall form of the building. After thousands of years’ development, there are now more requirements for the functions of windows and doors.

The windows and doors are requiring to be with more functions such as thermal break insulation, heat insulation, sound insulation, waterproofing, fire prevention, and, more importantly, energy-saving, and so on. The heat loss in the gaps between windows and doors in cold areas accounts for about 25% of the total heating consumption. The requirements for the tightness of windows and doors are essential content in energy-saving design.

The type of windows and doors for metal buildings

Since its development, windows, and doors have gone through four eras: wood, steel, aluminum alloy, PVC windows, and doors.

Wooden windows and doors are moderate in price, weak in appearance, poor in tightness, afraid of fire, flammable, easy to deform and crack. They are only suitable for low-grade, general places, high maintenance costs, and short life.

Steel welded windows and doors have low prices, low grades, natural corrosion, easy deformation, high maintenance costs, short service life, and are facing obsolescence.

Aluminum alloy windows and doors have excellent flame retardancy, luxurious appearance but poor integrity, easy deformation, poor thermal insulation, and weak sound insulation.

Aluminum alloy windows and doors for metal buildings have become the leading choices, due to their lightweight, ruggedness, corrosion resistance, proper sealing, and beautiful luster. Aluminum alloy ruggedness is the first choice for both ordinary houses and industrial buildings.

Let’s see the comparison of different profiles of windows and doors

| Profiles | Advantage | Disadvantage | Remark |

| Wood window & door | The unique texture and decorative effect, most affinity, low thermal conductivity of wood, high strength, environmental protection, can be processed into different shapes | combustible, easy to deform, difficult to repair after being damaged, easy to crack/scar, poor corrosion resistance, easy to be attacked by insects | Usually use for internal doors |

| Steel window & door | Good to large-scale production, high strength, easy processing, low cost, low operating management costs, and low prices. | Easy to rust, single shape, high thermal conductivity, poor decorative effect | Usually use for big roller shutter doors for warehouse or industrial buildings. |

| UPVC window & door | Low management and operating costs, price advantages, and corrosion resistance. | Poor angular strength, not resistant to yellowing, poor overall strength and easy to become brittle. | Not suitable for high-rise buildings, not suitable for places with severe or hot and humid climates. |

| Aluminum window & door | It is not easy to rust. Be suitable for large-scale industrial production. The price is relatively low, the weight is light, the handling is convenient, and the installation progress is fast. It can be made into very complex sections and structures and can be specially adapted for modification. fair price. | High thermal conductivity and poor sealing. Especially for sliding windows. | The most commonly used material. It can be used in various buildings, places, and different climate areas. |

| Thermal break bridge aluminum window & door | Improved technology, reduced thermal conductivity, better sound insulation, and good thermal insulation. | The cost is higher. Can not use for sliding windows. | Better quality than pure aluminum alloy windows and doors, but the price is higher. |

| Aluminum with wood window & door | High quality, can choose suitable wood grain decoration. Heat preservation, good energy-saving effect, and strong sealing performance. | The price is too high to make it widely application. | Suitable for residential, high-end office, hotel, etc. |

Below are different opening styles of windows and doors for metal buildings.

| Open styles | Advantage | Disadvantage | Remark |

| Fixed Window | Little accessories, low price. Good sealing. | It cannot open for ventilation. | Generally, it is not used alone, which is usually used with casement windows. Or use for the workshop for daylighting. |

| Casement window | Large opening area, good ventilation, good sealing performance, excellent sound insulation, heat preservation, and impermeability. The inside-opening window cleaning is convenient; the outside-opening does not take up space when opened. | The window is small so the view is not wide. It is easy to be damaged when the wind is strong. The inside window takes up some of the space in the room, and it is not convenient to use the screen window. | One of the most popular opening methods for residential and other buildings. |

| Sliding window | Simple and beautiful, large window, large glass block, wide field of vision, high daylighting rate, glass cleaning is convenient, flexible use, safe and reliable, long service life, open in one plane, occupy less space, and easy installation of screens | Two panels cannot be opened at the same time, and can only be opened at the half, the ventilation is relatively poor; sometimes the sealing is also slightly poor. | A sliding window is the most economical choice for residential or other buildings. |

| Casement door | Large opening area, good ventilation, good sealing performance, excellent sound insulation, heat preservation, and impermeability. | Takes up a certain opening space. | The most commonly used opening method for residential or other buildings. |

| Sliding door | Large glass block, wide field of vision, high daylighting rate, convenient glass cleaning, flexible use, safe and reliable, long service life, open in one plane, occupy less space | Two panels cannot be opened at the same time, and can only be opened at the half. | Usually use for bookcases, wall cabinets, bedrooms, living rooms, bathrooms or exhibition hall. |

| Awning window | It can be opened in two ways, either flat or pushed from above or below. It is a new form developed on the basis of casement windows. | The price is slightly higher. If you use poor-quality accessories, the window is more likely to break. | It can not only be ventilated but also ensure safety. Because there are hinges, the window can only open a ten-centimeter seam, and it can not reach out from the outside. |

The glass of windows and doors for metal buildings

Sure, except for the profiles and opening styles, you have to choose correct glass for your windows and doors. , the glass could be single, double glass, and triple glass. You could choose a suitable thickness according to the requirements.

1.Single glass: The thickness could be 3/4/5/6/8/10/12/15/19mm.

Single glass is a common choice if you have no enough budget.

2.Double glass

Double glass could divide into the hollow glass and laminated glass.

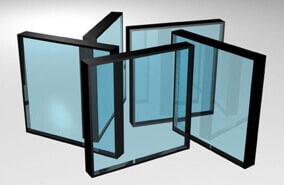

Hollow glass: Hollow glass is formed with two or more layers of flat glass by the infusion of desiccant and polysulfide adhesive.

Besides, the hollow chamber is full of dry air or vacuum or argon gas. Argon is an inert gas, its poor thermal conductivity than air, so filled with insulating glass can reduce the U-value, increasing insulation. For LOW-E insulating glass, argon also has a role in protecting the LOW-E film. Thickness could be 4mm-9A-4mm(16), 5mm-9A-5mm(19),6mm-9A-6mm(21),6mm-12A-6mm(24)etc.

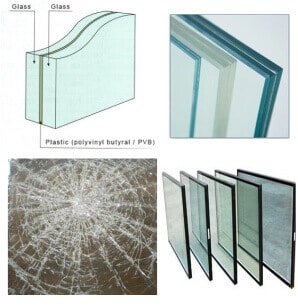

Laminated glass: laminated glass is two-layer glass sandwiched in the middle PVB, such as 6 + 1.14PVB + 6, the inner and outer glass 6mm, PVB thickness was 1.14 multiples of 0.38. There is 0.38,0.76,1.14,1.52.

The thickness is usually 3/4/5/6+0.38/0.76/1.14,1.52+3/4/5/6. Laminated glass is safer because of the middle layer film tough and strong adhesion, not easy to be damaged by the impact after through debris, will not fall off, and the film bonded together tightly. It is with better shock, anti-theft, bullet-proof, explosion-proof performance.

3.Triple glass: Triple glass is the same structure as hollow glass with much better sound and thermal insulation function.

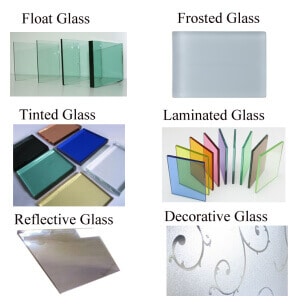

Of course, we have many different styles glass, such as standard float glass, tempered glass, laminated glass, tinted glass, frosted glass or obscure glass, reflective glass, decorative glass, low-E glass and so on.

1.Typical float glass: It is the original glass without future production. Then it is the most inexpensive glass.

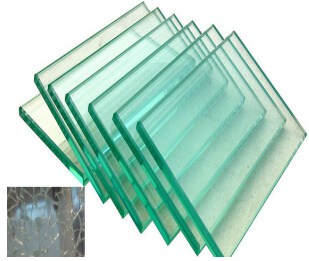

2.Tempered glass: Tempered glass/Reinforced glass belongs to safety glass. Tempered glass is a kind of prestressed glass. Chemical or physical methods usually used to form compressive stress on the glass surface.

When the glass subjected to external forces, it first cancels the surface stress, thereby improving the bearing capacity and enhancing the glass’s Wind pressure, cold and heat, impact, etc.

The advantages of Tempered glass

1)Safe: When an external force damages the glass, debris will be honeycomb-like, scrawled obtuse particles, not easily cause harm to the human body.

2)High strength: The same thickness of tempered glass impact strength and bending strength is 3 ~ 5 times of standard glass.

3)Thermal Stability: Tempered glass has excellent thermal stability, which can withstand big temperature difference, three times of conventional glass, it could withstand the 200-degree temperature changes.

3.Low-e glass: Low-e glass is also called Low radiation glass, on the glass surface plated film system of multi-layer metal or other compounds. Visible light through the coating layer and the high Cosco infrared reflection characteristics, make its compared with ordinary glass and traditional building coating glass, low e glass has excellent heat insulation effect and good light quality.

4. Other types of glass for choice: float glass, tinted glass, frosted glass or obscure glass, reflective glass, decorative glass are all could be made into single or double glass.

Significant knowledge of windows and doors for metal buildings

Standard glass for aluminum alloy doors and windows and plastic steel doors and windows includes ordinary float glass, tempered glass, colored glazed glass, coated glass, insulating glass, laminated glass, frosted glass, etc. At present, the following glass often uses in buildings:

- Common hollow glass is 5mm+12A+5mm, the hollow layer is 12mm, and the single glass on both sides is 5mm general glass;

- Tempered single glass, commonly used single piece of 5mm tempered glass, where there are requirements for safety glass configuration;

Ordinary home decoration and traditional factory buildings often use the above two glass configurations, which are economical and practical. - Double-layer tempered hollow glass 5mm+12A+5mm, the hollow layer is 12mm, and the single glass on both sides is 5mm tempered glass; the most commonly used glass in households is energy-saving, safe, and cost-effective.

- Laminated glass 5mm+0.76PVB+5mm, the middle glue layer of laminated glass thickness is 0.76mm, and the two sides are 5mm ordinary glass; if it is a matching profile, the thickness of the middle glue layer can be thickened. What we call bulletproof glass is laminated glass, which has relatively high safety performance. Especially in places with typhoons or lousy weather, laminated glass is more suitable.

- Low-e glass doors and windows with high energy-saving requirements. Generally, high-end residential areas or villas that require high-end doors and windows will require double-layer tempered glass and LOW-E coating, which is safe and energy-saving.

What kind of metal building needs tempered glass

- Floor-to-ceiling glass or glass doors and windows with a floor height of less than 900mm;

- Glass doors and windows with a single glass area of 1.5 square meters or more;

- Consider more safety indicators, such as multi-story, high-level, and children at home.

What kind of buildings needs Low-E glass

Low-E glass is the first choice in the energy-saving glass industry. It can save energy by 75% compared with ordinary single-piece glass and 40% with standard insulating glass. In addition, using Low-E glass can effectively save cooling and heating costs by about 50%. There are two series: colorless and colored. Colorless use in cold and temperate areas. Its visible light transmittance is more excellent than 70%. Its primary function is to block indoor heat energy from leaking to the outside. In winter, it allows sunlight to enter the room, thereby maintaining indoor temperature and saving heating costs; colored series are in tropical or subtropical regions. For regional use, it has a specific shading effect while preventing indoor heat from radiating outwards.

Performance of broken bridge aluminum profiles

The principle of the broken bridge aluminum alloy window is to use PA66 (containing 25% glass fiber) to separate and tightly connect the indoor and outdoor two layers of aluminum alloy into a whole, forming a new heat-insulating aluminum profile. Using this profile to make doors and windows have the same level of thermal insulation as that of plastic steel windows completely solving the fatal problem of aluminum alloys that conduct heat quickly and do not meet energy-saving requirements. Its outstanding advantages are good rigidity, super hardness, good fire resistance, excellent thermal insulation performance, high strength, large lighting area, atmospheric corrosion resistance, excellent overall performance, long service life, and good decorative effect.

According to the needs, you could choose a suitable glass for the windows and doors for metal buildings.