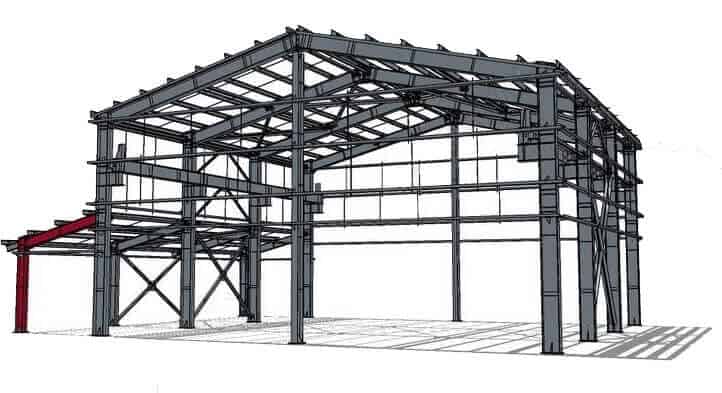

A steel portal frame structure is a type of low-rise building composed of steel columns and rafters joined by rigid…

What is Steel Structure Workshop Design?

Steel structure workshop design entails the strategic planning and construction of industrial facilities using primarily structural steel components. Renowned for its superior strength, adaptability, and cost-efficiency, steel has become the material of choice across a broad range of industries. A well-conceived steel workshop not only ensures operational safety and efficiency but also promises minimal maintenance and remarkable longevity.

Key Benefits of Steel Structure Workshops

Durability and Strength: Thanks to its exceptional strength-to-weight ratio, steel enables workshops to endure substantial loads and harsh environmental conditions, thereby maintaining structural integrity over extended periods.

Accelerated Construction Timelines: Prefabricated steel elements streamline the building process, dramatically reducing construction durations compared to traditional techniques.

Economic Efficiency: Steel structures minimize material waste, reduce labor requirements, and curtail ongoing maintenance costs, offering a highly cost-effective solution.

Design Flexibility: Steel’s adaptability allows for the seamless integration of heavy machinery, expansive equipment, and bespoke workspace configurations.

Sustainability: Being recyclable, steel contributes to eco-friendly construction practices, aligning with contemporary sustainability goals.

Core Design Considerations for Steel Workshops

Structural Layout and Spatial Planning

A thoughtfully designed structural layout is pivotal for maximizing a workshop’s operational efficiency. Critical factors include:

- Column Spacing: Optimized to facilitate unobstructed movement of equipment and personnel.

- Bay Dimensions: Tailored to accommodate industrial machinery and storage without sacrificing space efficiency.

- Crane Integration: Special structural provisions ensure the safe and effective installation of overhead crane systems.

For projects requiring expansive, open-sided layouts that facilitate maximum ventilation and accessibility, refer to our guide on Open-Type Steel Structure Workshops.

Precise Load Assessments

Accurate evaluation of load parameters safeguards structural stability:

- Dead Loads: Inherent weights of beams, columns, and roofing systems.

- Live Loads: Dynamic weights from operational machinery, personnel, and inventory.

- Environmental Loads: Regional factors such as wind speeds, snow accumulation, and seismic forces are meticulously considered.

Material Specification

Material selection critically influences the workshop’s functionality and resilience:

- Steel Grades: Grades such as Q235 and Q355 are commonly specified based on structural performance requirements.

- Cladding and Insulation: Protective and insulating panels not only enhance thermal performance but also improve weather resistance.

Environmental and Safety Provisions

Thermal Management and Ventilation

Maintaining optimal indoor climates is essential for both workforce comfort and operational efficiency:

- Insulation Solutions: Materials like fiberglass and rock wool mitigate heat transfer.

- Ventilation Systems: Mechanical and natural ventilation systems ensure adequate airflow and moisture control.

Fire Protection Strategies

Given steel’s vulnerability at elevated temperatures, fire resilience is paramount:

- Protective Coatings: Application of intumescent or fire-retardant coatings safeguards structural integrity.

- Fire Safety Infrastructure: Sprinkler systems, alarm networks, and clearly delineated evacuation routes enhance onsite safety.

Corrosion Mitigation

Longevity of steel workshops hinges on robust corrosion protection measures:

- Galvanization: Zinc coatings effectively shield steel components from oxidative damage.

- Efficient Drainage: Steel structure workshop design strategies prioritize swift water evacuation to prevent structural deterioration.

Incorporating Modern Technologies

Building Information Modeling (BIM)

Leveraging BIM enhances project precision, fosters multidisciplinary collaboration, and streamlines lifecycle management from design through to maintenance.

Smart Infrastructure Integration

Embedding IoT technologies facilitates continuous monitoring of structural health, energy usage, and maintenance requirements, thereby improving operational resilience.

Regulatory Compliance and Quality Assurance

Adherence to relevant building codes and industry standards ensures not only legal conformity but also optimal performance:

- Local Building Regulations: Steel structure workshop design to meet stringent safety, environmental, and structural codes.

- Quality Certifications: Regular inspections and compliance with certifications such as ISO standards reinforce operational excellence.

Practical Applications and Case Studies

Empirical evidence illustrates the versatility of steel workshops:

Manufacturing Plants: Automotive and industrial production facilities exploit steel’s adaptability to house complex automated systems.

Warehousing and Logistics Centers: Clear-span steel workshops provide unmatched spatial efficiency for inventory management.

FAQs about Steel Structure Workshop Design

1. What advantages does a steel structure workshop offer over traditional constructions?

Steel workshops boast faster construction, lower maintenance costs, superior durability, versatile designs, and environmentally sustainable attributes.

2. What is the typical construction timeframe for a steel structure workshop?

Depending on size and complexity, projects may complete within a few weeks to several months, particularly with prefabrication techniques.

3. Which insulation materials are commonly used?

Efficient and cost-effective options include fiberglass, rock wool, and insulated metal panels.

4. Why is crane integration vital in steel structure workshop design?

Overhead cranes significantly enhance material handling efficiency; hence, workshop structures must accommodate their operational demands.

5. How are fire risks mitigated in steel workshops?

Through fire-resistant coatings, sprinkler systems, alarm installations, and strategic evacuation planning.

6. Are steel structure workshop design capable of withstanding severe weather?

Absolutely; properly engineered steel workshops resist extreme weather phenomena, including heavy snowfall, high winds, and seismic disturbances.

7. Can steel structure workshops be expanded in the future?

Steel designs offer exceptional adaptability, enabling straightforward expansions or structural modifications.

8. What factors most influence the cost of a steel structure workshop?

Key determinants include structural dimensions, material quality, design complexity, insulation specifications, geographic location, and regulatory compliance.

Conclusion

Mastering steel structure workshop design demands a holistic approach that balances structural ingenuity, regulatory compliance, technological integration, and environmental responsibility. By meticulously addressing every phase of design and execution, organizations can establish workshops that not only fulfill immediate operational requirements but also adapt seamlessly to future growth and technological advancements, thereby ensuring enduring value and resilience.