A steel portal frame structure is a type of low-rise building composed of steel columns and rafters joined by rigid…

In today’s fast-evolving industrial landscape, construction strategies must prioritize speed, adaptability, and long-term resilience. Traditional methods—while reliable in static environments—often lack the responsiveness required by modern manufacturing, warehousing, and logistics operations. Against this backdrop, metal building kits for industrial use have gained traction as a pragmatic solution that blends efficiency, scalability, and cost control.

At Havit Steel, we’ve observed a clear shift among clients toward prefabricated systems that reduce downtime and enhance layout flexibility. These kits, typically manufactured from structural steel, arrive on-site as complete, ready-to-assemble packages. Their ability to accommodate unique workflows and expand alongside growing operations makes them a preferred choice for diverse sectors, including logistics, food processing, and energy distribution.

What Are Metal Building Kits?

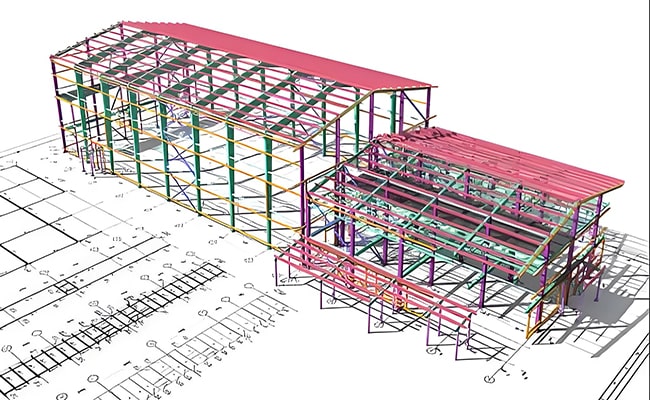

A metal building kit includes pre-engineered components—such as beams, columns, wall and roof panels, bracing, fasteners, and optional insulation—manufactured in factory-controlled settings to ensure dimensional accuracy and consistent quality. These kits comply with standards such as Q355B for structural steel and are engineered in line with local seismic and wind load requirements.

Designed specifically for industrial use, these systems can support column-free interior spans exceeding 30 meters, integrate with crane systems, and maintain load-bearing performance under high live and dead loads.

Key Advantages of Metal Building Kits for Industrial Use

1. Accelerated Construction Timelines

In practice, we’ve seen clients reduce total construction periods by up to 40% compared to concrete alternatives. Pre-cut and pre-labeled components reduce on-site labor, minimize weather-related delays, and speed up commissioning. For example, in a recent cocoa bean facility project, installation was completed in under eight weeks—cutting weeks off the expected delivery.

2. Economic Efficiency

By reducing labor intensity and enabling leaner foundations, metal kits lower upfront investment and operating costs. Additionally, standardization leads to predictable pricing and fewer material overruns, a common concern in traditional builds.

3. Modularity and Future Expansion

Metal building kits for industrial use often evolve with technological upgrades or changes in capacity. The modular design of these steel kits allows clients to expand laterally or vertically without major structural revisions. One client in Côte d’Ivoire doubled their storage area within two years of the initial build using bolt-on framing extensions.

4. Structural Strength and Durability

Steel building kits manufactured to GB50017-2017 or EN 1993 (Eurocode 3) standards provide exceptional resistance to seismic and wind events. With the application of epoxy zinc-rich coatings and galvanized finishes, these structures can remain operational for 40+ years with minimal corrosion-related maintenance.

5. Customizable Layouts

From ceiling heights tailored to forklift operations to natural light optimization through translucent panels, metal building kits can be adapted to your facility’s functional goals. Our design engineers routinely collaborate with clients to align column placement, ventilation, and insulation specifications with workflow efficiency and equipment requirements.

Industrial Use Cases: Function Meets Flexibility

Manufacturing Facilities

Our clients in the automotive and agricultural sectors benefit from clear-span interiors that streamline assembly line configurations and ease material flow.

Maintenance and Repair Workshops

For facilities with overhead crane systems or servicing heavy vehicles, we offer reinforced steel kits that support multi-ton crane bridges and mezzanine access platforms.

Warehousing and Bulk Storage

From dry goods to cold storage, steel warehouses offer flexible zoning, quick reconfiguration, and long-term ROI. One logistics customer in Nigeria reported a 22% increase in throughput efficiency due to improved racking layout in their prefabricated facility.

Logistics and Distribution

These kits support high bay storage and multiple loading docks. Faster construction means quicker returns. In Southeast Asia, a cross-docking center was operational 35 days after ground-breaking.

Energy and Utility Infrastructure

Power substations, water treatment plants, and solar inverter stations require robust, compliant enclosures. Steel kits satisfy performance and regulatory demands while offering superior transportability.

Planning Considerations for Industrial Steel Buildings

Effective planning involves technical due diligence in areas such as:

Future-Proofing: Structural zoning for eventual expansion, additional floors, or mezzanine insertion.

Load Calculations: Including static loads from stored goods and dynamic forces from cranes and mechanical systems.

Climate Adaptation: Incorporating ridge vents, wall louvers, or insulated roof panels to mitigate heat gain or humidity.

Natural Lighting: Using translucent wall sheets or ridge skylights to reduce operational energy costs.

Code Compliance: Designs aligned with CECS102:2002 (for portal frames), local fire protection ordinances, and wind load maps.

Case Study: Cocoa bean processing workshop in Côte d’Ivoire

This facility is a representative example of how metal building kits for industrial use can be tailored to meet complex operational requirements in real-world production settings.

One illustrative project involved a 48m x 176m processing workshop in San Pereiro, Ivory Coast. The building featured a standard eave height of 7 meters, with a 20-meter clearance in the equipment zone to house vertical processing lines. Our engineers customized the steel framing to accommodate the client’s machinery layout and ventilation ducting, with integrated crane support built into the primary beams.

This project underscores the design versatility inherent in steel structures. By tailoring different structural forms to match the functional demands of each production zone, the building layout was optimized to support a smooth and continuous workflow. The incorporation of large-span elements eliminated the need for internal columns, significantly enhancing the usable interior space for both machinery installation and material storage. This spatial efficiency, coupled with the modular adaptability of steel systems, contributed to a facility that is not only robust and purpose-driven but also readily scalable for future industrial growth.

Sustainability Benefits of Metal Building Kits

Steel kits align closely with modern sustainability benchmarks:

- Reduced Material Waste: Fabrication accuracy limits site scrap.

- Lower Emissions: Fewer site deliveries and shorter construction cycles.

- Energy Efficiency: Rock wool panels (≥ R-30) reduce HVAC demand.

- Lifecycle Durability: With coatings, buildings last 40+ years with minimal intervention.

These attributes support clients pursuing LEED, EDGE, or BREEAM certifications.

Why Choose Havit Steel for Industrial Building Kits?

At Havit Steel, we don’t just deliver structures—we deliver strategic assets. Our engineers and project managers collaborate with clients from concept through commissioning. Here’s how we add value:

- Design planning tailored to operational flow and load types

- Structural calculations and fabrication to international standards

- Field-proven installation manuals and remote technical support

- Global shipping with compliance documentation for customs and approvals

Whether your need is a modular plant expansion or a new industrial complex, we provide the engineering insight and manufacturing discipline that ensures project success.

Frequently Asked Questions (FAQs)

How long does it take to install a metal building kit?

Typical timeframes range from 30 to 60 days depending on building size, crane work, and local permitting timelines.

Can your kits support cranes or heavy equipment installations?

Yes. We design for top-running or underhung cranes, mezzanines, and vibration-isolated machinery.

Do your structures comply with safety codes?

Absolutely. Our designs follow standards such as GB50017, Eurocode 3, and local seismic zoning laws.

Can buildings be extended later?

All Metal building kits are modular by design and can be extended with bolt-on components or retrofitted mezzanines.

What insulation options do you offer?

We offer PU sandwich panels, rock wool, and fiberglass insulation systems, rated up to R-40 for cold storage applications.

Conclusion: The Future of Industrial Construction is Prefabricated

In an era where agility defines success, metal building kits for industrial use present a clear competitive edge. By accelerating construction timelines, reducing costs, and enabling scalable layouts, they empower businesses to respond rapidly to market demands while maintaining operational excellence.

At Havit Steel, we build more than just enclosures—we build systems that support productivity, growth, and long-term value.