In response to the growing demand for climate-resilient and scalable industrial infrastructure in West Africa, Havit Steel Structure has designed…

With the increased production capacity, structural steel has become a widely used building material due to its excellent mechanical properties. Thanks to its high strength, good ductility, and excellent seismic performance, it occupies a core position in steel structure buildings. Compared with traditional concrete structures, structural steel is lightweight and can reduce the overall load of the building. Therefore, it has become an indispensable building material in workshops, warehouses, bridges, and high-rise buildings.

1. What is Structural Steel?

Structural steel refers to a specific category of steel tailored for use in load-bearing and structural applications. It is engineered through precise metallurgical processes and exhibits a unique combination of strength, ductility, and weldability, making it indispensable in modern construction. Unlike general-purpose steel, structural steel is designed with strict chemical composition and mechanical property standards to ensure consistent performance under various stresses and environmental conditions.

Structural steel is valued at its core for supporting substantial weight while maintaining geometric stability. Carbon, manganese, and micro-alloying components are deliberately balanced to enhance its mechanical behavior, particularly under tensile and compressive forces. This fine-tuned material forms the skeletal framework of buildings, bridges, and industrial facilities, enabling the construction of expansive spans and vertical heights with minimal material mass.

What distinguishes structural steel in practice is not only its physical robustness but also its adaptability. It can be fabricated into numerous standard shapes, assembled with high precision, and integrated into traditional and contemporary architectural designs. As a result, it stands as a foundational material in engineering practice and infrastructure development.

2. Structural Steel Types and Grades

Structural steel encompasses various types and grades, each engineered to meet distinct performance criteria across diverse construction scenarios. Chemical composition, processing techniques, and microstructure variations impart unique mechanical properties that make each category suitable for specific structural demands. A clear understanding of these distinctions is essential for material selection in engineering design.

2.1. Carbon Steels

Carbon steels constitute the most foundational category within structural steel classifications. Characterized by a relatively simple chemical profile—primarily iron with varying carbon content—these steels offer a cost-effective balance of strength and workability. Their mechanical behavior is influenced mainly by carbon concentration, which affects hardness, ductility, and tensile strength.

Despite their economic and structural advantages, carbon steels are not without limitations. They typically exhibit lower resistance to corrosion and environmental degradation, making them more suitable for indoor or low-exposure applications unless adequately protected. Widely used grades such as ASTM A36 are frequently found in general-purpose framing, bridge components, and industrial platforms.

2.2. High-Strength Low-Alloy Steels

High-strength low-alloy (HSLA) steels significantly advance over traditional carbon steels. By incorporating elements such as copper, nickel, vanadium, and niobium, HSLA steels achieve enhanced strength-to-weight ratios, improved atmospheric corrosion resistance, and superior weldability.

These materials are especially valuable in large-scale infrastructure projects where both structural efficiency and environmental resilience are critical. Grades like ASTM A572 and A588 are common in seismic zones, long-span bridges, and weather-exposed building frameworks. Their performance characteristics make them a material of choice when engineering demands intersect with durability requirements.

2.3. Forged Steels

Forged structural steels are produced by applying intense compressive force to heated billets, resulting in a refined internal grain structure and elevated mechanical performance. This thermomechanical transformation confers superior strength, fatigue resistance, and toughness compared to standard rolled or cast steel.

Due to their enhanced properties, forged steels are typically employed in high-stakes applications—such as pressure vessels, industrial crankshafts, and components subjected to dynamic stress—where failure is not an option. Their use in structural systems may be limited by cost and fabrication complexity, yet in critical load-bearing scenarios, they remain indispensable.

2.4. Quenched and Tempered Alloy Steels

Quenched and tempered steels undergo rigorous heat treatment processes that optimize their hardness, ductility, and toughness. Quenching involves rapid cooling from high temperatures to lock in a martensitic microstructure, while tempering subsequently alleviates brittleness, resulting in a steel grade that is both strong and resilient.

These steels are well-suited for environments involving high-impact loads, temperature fluctuations, or aggressive stress conditions. Structural applications include high-rise building frames, heavy equipment supports, and long-span trusses. Their performance under duress renders them critical to projects where safety margins must be stringently maintained.

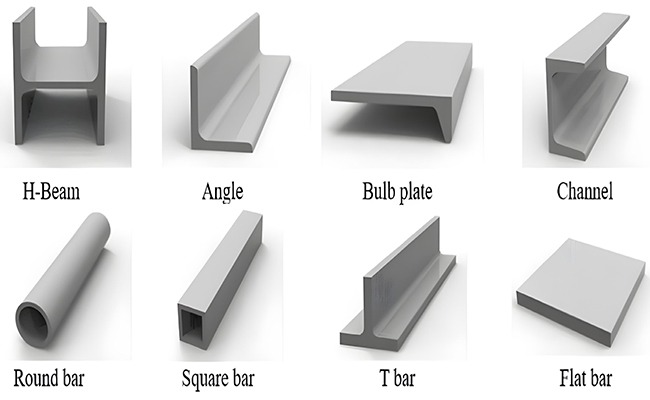

3. Standard Common Structural Steel Shapes

Structural steel is manufactured in various standardized shapes, each engineered to fulfill distinct structural functions. These forms are not arbitrary; they reflect centuries of engineering refinement to optimize material distribution, load transfer efficiency, and constructability. The selection of a particular profile is informed by the type of forces it must resist—bending, compression, tension, or torsion—and by spatial, architectural, and economic constraints.

I-Beams and H-Beams

Perhaps the most iconic structural forms, I-beams (also known as H-beams or universal beams) are distinguished by their high moment of inertia along the vertical axis. This configuration provides exceptional bending resistance, making them ideal for horizontal spans such as floor systems, bridges, and roof girders. The broad flanges of H-beams further enhance load distribution and facilitate efficient connections with other structural elements.

Angle Sections (L-Shapes)

Angle steels are characterized by their L-shaped cross-section and are commonly employed in bracing systems, edge reinforcement, and secondary framing components. Their asymmetrical geometry makes them highly efficient in carrying loads along two axes, and they are frequently used in trusses, lattice towers, and purlin systems. Though compact, their contribution to overall structural stability is often critical.

Channel Sections (C-Shapes)

Channel sections, or C-beams, provide versatile load-bearing options where partial symmetry and open flanges are advantageous. Their geometry suits short-span beams, wall studs, or intermediate support members in steel framing systems. Due to their open side, however, they require careful orientation to avoid lateral-torsional buckling under certain load conditions.

Flat Steel

With its simple and versatile rectangular profile, flat steel is commonly used for applications requiring precise and consistent strength distribution across its plane. Flat steel is often found in base plates, structural connectors, and support components and is integral to the foundation of many steel-framed structures. Its flat surface also allows easy fabrication processes, including welding and bolting, making it a fundamental component in primary and secondary steel framing systems.

Circular Tubes

Circular tubes, also called round hollow sections, offer superior strength and structural integrity with their symmetrical, closed geometry. Their resistance to torsional loads makes them ideal for use in columns, masts, and trusses where axial and twisting forces must be efficiently absorbed. Due to their smooth surface and aesthetically pleasing form, circular tubes are also employed in architectural applications where visibility is paramount. Their ability to distribute stress evenly makes them highly durable in seismic and high-wind environments.

Hollow Structural Sections (HSS)

Hollow structural sections—including rectangular, square, and circular profiles—combine aesthetic appeal with structural efficiency. Their closed geometry offers uniform strength in all directions, making them ideal for columns, exposed architectural elements, and tubular trusses. Due to their torsional rigidity and compact form, HSS members are especially valued in seismic and wind-resistant design.

T-Shapes and Z-Shapes

Though less ubiquitous, T-shaped and Z-shaped sections serve specialized roles. T-sections are often employed in composite floor systems or flange extensions, while Z-sections frequently use cladding and roofing frameworks, particularly in pre-engineered buildings. Their asymmetrical form allows for interlocking and nesting, facilitating modular construction and lightweight system integration.

Each shape is manufactured under rigorous dimensional tolerances, with standards such as ASTM A6 or EN 10034 ensuring interoperability and structural reliability across projects. These profiles’ rational selection and configuration form the backbone of modern structural design, balancing performance with economy.

Advantages and Disadvantages of Structural Steel

A combination of material efficiency, mechanical performance, and long-term viability drives the adoption of structural steel in modern construction. However, like all engineered solutions, its benefits are accompanied by specific limitations. A nuanced understanding of both is necessary for informed material selection and risk management in structural design.

4.1. Higher Strength-to-Weight Ratio

One of structural steel’s most defining attributes is its superior strength-to-weight ratio. This characteristic allows for lighter structures without compromising load-bearing capacity, enabling longer spans, taller buildings, and reduced foundation loads. This property is indispensable in high-rise construction and bridge engineering, where gravity and lateral forces must be managed within strict spatial and weight constraints.

Moreover, high-strength steel facilitates material savings and supports architectural innovation by reducing the need for bulky support members. However, designers must carefully consider local buckling and stability issues arising from slenderness ratios inherent to lightweight sections.

4.2. High Durability

Structural steel exhibits excellent durability when adequately protected against corrosion. Its resistance to fatigue, wear, and mechanical deformation under cyclic loading conditions ensures a prolonged service life, especially in industrial and infrastructure applications. Modern protective coatings, galvanization, and weathering steel compositions have significantly expanded its applicability in aggressive environmental settings.

Structural steel remains susceptible to oxidation and corrosion without proper surface treatment and maintenance—particularly in marine or high-humidity environments. Durability, therefore, is closely tied to long-term maintenance strategies and environmental context.

4.3. Versatility Due to Good Ductility

The ductile behavior of structural steel is a key advantage in design flexibility and structural safety. Ductility allows the material to deform plastically under stress without sudden failure, providing essential warning signs before collapse. This property is especially valuable in seismic engineering, where energy absorption and redistribution are critical.

From a construction standpoint, steel’s malleability enables a wide range of fabrication options—cutting, welding, bolting, and rolling—making it amenable to complex geometries and modular construction techniques. The ability to adapt and be reshaped precisely allows steel to accommodate evolving architectural demands and retrofitting requirements.

4.4. Sustainability

Structural steel contributes significantly to sustainable construction practices due to its recyclability and resource efficiency. Steel is one of the most recycled materials worldwide, with recovery rates exceeding 90% in many industrial contexts. This high recyclability reduces the demand for virgin ore extraction and lowers the embodied energy of construction materials.

In addition, steel structures’ prefabrication potential minimizes on-site waste, shortens construction timelines, and enhances quality control. While steel production remains energy-intensive, advances in manufacturing processes and circular economy strategies continue to improve its environmental performance profile. When evaluated across the lifecycle of a building or infrastructure system, structural steel often aligns well with long-term sustainability objectives.

5. What is Structural Steel Used For?

Structural steel serves as a cornerstone material in modern construction and infrastructure development. Its mechanical reliability, adaptability to diverse design schemes, and compatibility with industrialized fabrication methods have positioned it as a fundamental element in various engineering applications.

5.1. Framework for Commercial Construction

Structural steel is widely used in commercial architecture to form the primary skeletal framework of office towers, shopping complexes, and mixed-use developments. Its capacity to accommodate long, column-free spans facilitates open floor plans—an essential feature in retail and corporate environments. Additionally, steel’s high strength allows for vertical scalability, enabling the construction of high-rise buildings that remain structurally sound and spatially efficient.

5.2. Framework for Workshops and Manufacturing Facilities

The industrial sector has long favored steel for constructing production halls, warehouses, and assembly plants. Steel’s ability to support wide spans with minimal internal obstructions is advantageous for housing large machinery and enabling flexible workflow layouts. Steel’s prefabrication potential accelerates project timelines and ensures structural precision—key priorities in time-sensitive manufacturing operations.

5.3. Framework for Civil Steel Frame Buildings

Structural steel in civil architecture, such as hospitals, schools, and civic centers, enables modular construction and rapid assembly while maintaining high safety standards. Its ductility and predictable behavior under seismic or wind loads make it an ideal material for buildings located in hazard-prone regions. Furthermore, steel framing systems facilitate future renovations or vertical extensions, allowing public infrastructure to evolve with societal needs.

5.4. Material for Road Bridges

Structural steel is extensively employed in bridge engineering due to its exceptional strength-to-span capacity and adaptability to varied geometric configurations. From short-span overpasses to complex suspension bridges, steel allows for streamlined construction while minimizing dead load. Its high fatigue resistance under cyclic vehicular loads and ease of maintenance make it suitable for urban and rural bridge networks.

5.5. Used in C and Z Purlins for Corrugated Roof Construction

Structural steel fabricates C and Z-shaped purlins in light-gauge framing systems that provide secondary support to corrugated metal roofs. These components distribute loads to primary structural members and help resist uplift forces caused by wind. Their roll-formed geometry offers high dimensional consistency, and their lightweight nature facilitates quick installation—making them a staple in prefabricated and industrial roofing systems.

6. FAQS about Structural Steel

Q1: How does structural steel differ from reinforcement steel (rebar)?

Structural steel refers to load-bearing steel components such as beams, columns, and trusses designed to carry structural loads independently. Rebar, by contrast, reinforces concrete, primarily enhancing its tensile strength. The two serve distinct functions within structural systems and are rarely interchangeable.

Q2: Can structural steel be used in earthquake-prone areas?

Yes. Structural steel is particularly well-suited for seismic regions due to its high ductility and energy dissipation capabilities. Properly designed steel frames can absorb and redistribute seismic forces, reducing the likelihood of catastrophic failure during earthquakes.

Q3: Is structural steel fire-resistant?

While steel is non-combustible, it loses strength at elevated temperatures. Therefore, fire protection measures—such as intumescent coatings, fire-resistant cladding, or sprinkler systems—are essential to preserve load-bearing integrity during a fire event.

Q4: What are the typical lifespans of structural steel buildings?

With adequate design, protective treatment, and maintenance, structural steel buildings can last 50 years or more. In many cases, the steel frame outlives the function of the building itself and can be reused or recycled for future applications.

Q5: How does structural steel contribute to sustainable construction?

Steel is one of the most recycled materials globally. Its capacity for reuse without significant degradation, precision fabrication, and reduced on-site waste supports sustainable building practices and life-cycle efficiency.