There are many ways to classify building steel structures. According to the structure type, they are portal frame, steel frame,…

The steel warehouse buildings installation is the steel components, which are prefabricated at the factory and delivered to the project site for install.

The process of steel warehouse buildings installation:

- Preparation of the site: This includes clearing the site, leveling it, and preparing the foundation.

- Erection of the steel frame: The steel frame of the building is constructed and bolted together on site.

- Attaching panels: The steel panels, which serve as the walls and roof of the building, are attached to the frame.

- Installing doors and windows: The required doors and windows are cut out of the panels and installed.

- Adding insulation: Insulation is installed in the walls and roof to provide thermal protection.

- Finishing: The interior and exterior surfaces of the building are finished, typically with drywall and paint, respectively.

- Utility installation: Plumbing, electrical, and HVAC systems are installed as required.

This process may vary depending on the size, design, and complexity of the installed steel warehouse building, but the above steps provide a general overview.

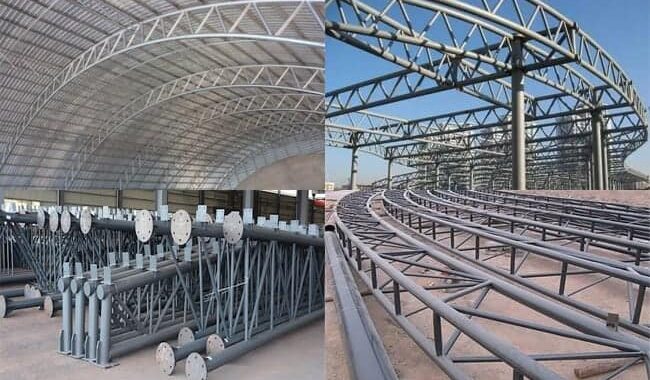

Installation Sequence of Metal Structures

1. Hoisting of Primary Structure: Assembling roof beams on the ground, erecting steel columns, hoisting steel beams, connecting secondary structure, correcting primary structure deviations, installing crane beams, and mezzanine structure (optional).

Leading control quality: The deviation of the primary structure should meet the specifications and design requirements, and the high-strength bolts should meet the conditions at the beginning and end.

2. Secondary structure installation: tie rods, roof purlins, wall girt, roof and wall bracing, sag rod, etc.

Installation Sequence of Wall and Roof Panel

1. Roof panel and insulation cotton installation: Install insulation cotton first, then install the roof panel (lay wire mesh under the insulation cotton to prevent the insulation cotton from falling off)

Primary quality control: The roof panel is mainly a waterproof problem. So it depends on the overlap between the metal sheet, nailing. And the fullness of the glue. The glue should wipe clean. The coating on the surface should not damage to prevent rust.

2. Wall panel installation: It is mainly wall insulation and wall panel installation.

Leading control quality: the wall surface is mainly an aesthetic problem and a window place waterproof problem. There is also the problem of installation deviation. For example, the bottom must flat, and the flatness deviation between the wall sheet must meet the requirements.

3. Trim and flashing installation: Gabe trims between the roof and wall, wall corner trim at the corner of the wall, the base trim between the wall panel and brick wall, the door and window trim, and so on.

Primary quality control: Trim and flashing are the last steps, and one of the main items of beautiful projects, so horizontal and vertical, is the most basic.

During the construction of the prefab steel warehouse buildings, as long as the installation completed in strict accordance with the construction process and corresponding procedures, so it can effectively avoid engineering problems caused by operating errors and speed up the progress of the project.

The quality control of steel warehouse building installation:

1. Before installing the steel warehouse building, the quality of the steel structure should check. If the permanent deformation and defect of the component exceed the allowable value, should deal with it.

2. For the installation of steel columns, check whether the shim under the column baseplate is solid and flat to prevent the anchor bolts under the baseplate from becoming unstable.

3. Whether the steel column is vertical and there is no displacement, during the installation process, before the structure has not formed a stable system, temporary support measures should take.

4. When the steel structure installed to create a space fixed unit, and after passing the acceptance check, the construction unit required to promptly pour the scope of the column bottom plate and the top surface of the foundation with expanded concrete.

5. Check the verticality and overall plane bending of the main structure of the steel warehouse building.