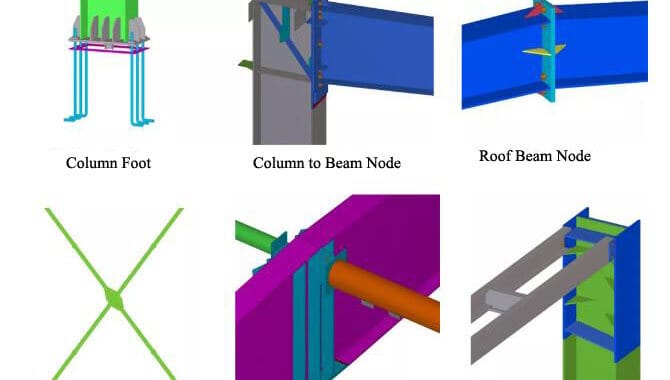

Steel structure splicing includes splicing in the workshop and on-site. The splicing methods include welding and bolting. We should implement…

The Steel Structure Workshop building is increasingly used in modern industrial production. Some of the products produced by the manufacturers go directly to the market, but most of the products have stocks, which require a particular inventory in the warehouse. The fundamental difference between the factory and warehouse buildings is not much, just one for production or storage. Nowadays, the use of the steel structure workshop is also more and more extensive, so how to build a qualified steel structure workshop, we are ready to start with the various processes of Steel Structure Workshop Construction.

The processes of Steel Structure Workshop Building:

1. Design: design is the source of all working procedures; thoughtful design can make construction twice as fast, and only with the design scheme construction personnel can have a direction.

2. Production: Production follows the design of the processing of steel components.

The Production Process

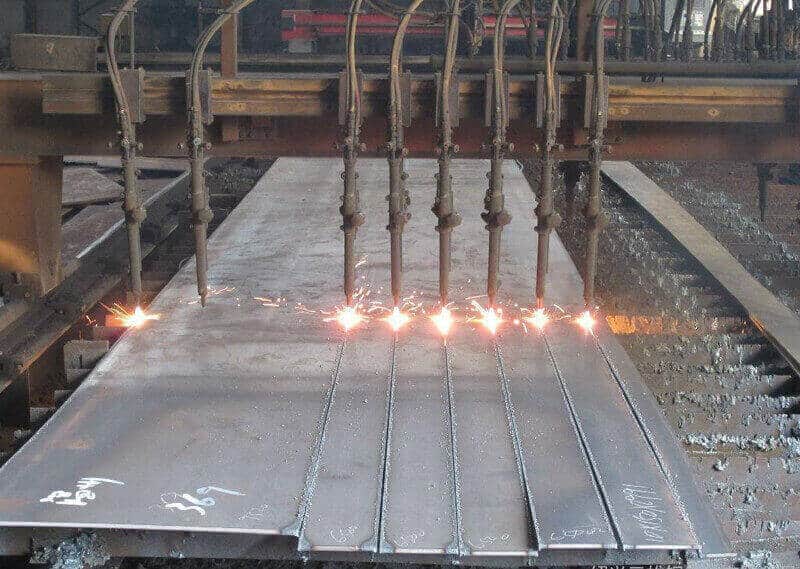

1)Cutting

Steel plate cutting is used to process steel components formally. The quality of the cut has a direct impact on the following process. If the cutting is not careful, it may cause the material to become a pile of scrap iron. Quality control is significant.

2) Welding

Steel plate cutting is used to process steel components formally. The quality of the cut has a direct impact on the following process. If the cutting is not careful, it may cause the material to become a pile of scrap iron. Quality control is significant. The procedure belongs to concealed engineering and is one of the most comfortable quality problems, so it is necessary to ensure enough welding strength to ensure the component’s durability.

3) Painting

The painting is also a hidden process, which significantly impacts the service life of the steel structure building. The excellent coating can do the steel structure workshop for a long time will not rust, not easy to destroy, and increase the service life of Steel Structure Buildings.

3. Installation: This working procedure plays an essential role in the engineering quality, and its quality is greatly influenced by the above working process and the whole steel structure workshop.

The Installation Process

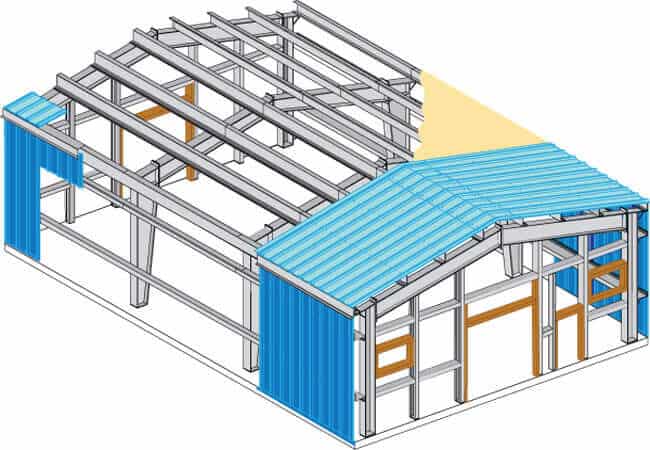

1) Hoisting of the main structure

Joint the roof steel beam on the ground, install steel column, hoisting Steel Beam, connecting secondary structure, correcting significant structure deviation, installing crane beam (optional), raising interlayer (optional), fireproof coating.

Main Control Quality: the main structure deviation should meet the specifications and design requirements, and high-strength bolts should meet the needs of the steel structure workshop.

2) The installation of the secondary structure

Roof purlin, wall girt, fly bracing, wall and roof cross bracing, and so on.

3) The installation of the roof panel and insulation

First, lay the insulation layer, then install the roof panel (some projects in the insulation layer put the steel wire Mesh to prevent the insulation layer fall off, this mainly depends on the insulation layer level)

The leading control quality: the roof is primarily waterproof, so to see the board and board lap joint, nail case, the glue coating is complete, the glue place should be wiped clean, and the plate surface coating should not destroy to prevent rust, etc.

4) The installation of the wall panel

It is the insulation and wall panel installation of the steel structure workshop.

Main Control Quality: There is also the problem of installation deviation, such as the bottom to flat, the whole plane to flat, plate, and plate between the flatness deviation to meet the requirements.

5) The installation of trim and flashing

Install trim and flashing, such as the corner trim between the roof and wall, corner trim of the wall, the flashing between the brick wall and wall panel, doors, and windows trim.

Why build the steel structure workshop?

It is necessary to choose the appropriate construction method to improve the quality and service life of the steel structure workshop. Especially for the load-bearing members of some steel structure workshop buildings, it is necessary not only to strengthen the quality control in the field construction process but also to adopt a scientific and practical design scheme, to ensure the structural stability and safety of the Steel Structure Workshop.

The advantage:

The construction time of the steel structure workshop is short; all steel components are processed and prefabricated in the factory and installed on the site, which saves time and labor costs.

Using a steel structure to build the workshop building is very reasonable to save costs. The manufacturer of the Steel Structure Workshop components can realize the industrialized production with high precision and only need to transport to the construction site for installation; the construction steps that need to process to the construction site are simplified. The constructors of the steel structure workshop should carefully examine the drawing requirements before installation, arrange the constructors reasonably, and provide a quality guarantee for the installation of the steel structure workshop.

The disadvantage

But some problems with steel structure workshop also need attention; steel structure workshops long-term exposure to the air, natural corrosion, and weak fire resistance are worthy of consideration. In the chemical plant, the molecular activity of metallic materials is much more active than that of concrete materials, and it is easy to react with elements in the air to cause corrosion of steel structures. There are also precedents in fire resistance, and many building fires are caused by melting steel at high temperatures. Steel structures are not fire-resistant. As the increase of heat, the yield point and strength of the steel structure will decrease. Thus the performance of steel structure workshops will also decrease and will collapse, so it is necessary to improve the anti-corrosion and fire resistance of the Steel Structure Workshop.

Single-story Steel Structure Workshop Building:

Single-storey Steel Structure Workshop building is an industrial factory building with a single-story steel structure as the main body. Single-story steel structure workshops are often used for large machinery and equipment or massive lifting transport equipment factories, such as metal and plastic, mechanical equipment, printing paper products, molds, and other industries. The Exterior Wall and the roofing part generally use the corrugated single-color sheet.

The characteristics and application of steel workshop building:

1. The characteristics

Large span and space and various load forms often bear the dynamic load and moving load (such as crane load, power equipment load, etc.). The column is to carry roof load, wall load, crane load, and the seismic capacity of the main components; The requirement of geological exploration is higher. The single-story Steel Structure Workshop often uses fitting structure standardization.

1) length: unlimited

2) Span: 12 ~ 50 meters clear span

3) Height: The drip water level of the single-story steel structure workshop is significant; some workshop height is 4-5 meters, some 6-7 meters, and some can be as high as 11-12 meters or higher. Generally, the higher the steel structure workshop will be more challenging to build, the cost of materials required will be more expensive.

4) Internal structure: There is a bracket workshop to load the crane, this is an essential part of industrial production; many work machinery and equipment and heavy production materials need a crane, so it must install the bracket and crane.

5) External structure: single layer color steel sheet and sandwich panel.

2. Application:

The single-story Steel Structure Workshop is the primary type of workshop and warehouse in Metallurgy, machinery, and other industries. Many workshops choose a single-story steel structure workshop mainly because of its large span and the height that can adjust to the need.

Design points of single-story steel structure workshop

Production lines are generally arranged in a horizontal direction in a single-story steel structure workshop. This kind of factory building has a simple structure and can use large spans and extensive lengths; it is convenient to use heavy lifting and transportation equipment, and heavy equipment can be installed on the ground; skylights can be used for lighting and ventilation. The single-story factory building has strong adaptability and can produce heavy-duty and light-duty products; it can be built into large-span and large-area or small-span and small-area.

Single-story steel structure workshops can be single-span or multi-span, and each span can be arranged parallel or vertical. Most workshops are rectangular, and some thermal processing workshops use a п shape.

The column spacing of the single-story steel structure workshop is usually 6 meters or 9, 12, 18 meters, etc., and the span is also 20 meters as the fundamental parameter to facilitate the finalization of the components. The height of each span of the multi-span factory building is different and should be adjusted appropriately to simplify the elements and structural processing and change the lighting and ventilation effects.

Structural layout principles of single-story steel structure workshop:

1. Lateral anti-lateral force system

Frames, portal frames, cantilever columns, or steel structures are steel-jointed or hinged with roof beams and column tops. The long factory building’s ordinal lateral force resistance system adopts the inter-column support, and the rigid frame structure can also be adopted when the conditions are limited.

2.Carrying capacity

When the roof beam and the top of the column are hinged, bolts are used. When the beam is a solid web beam, to ensure that the node connection has sufficient bearing capacity, it is provided that the node and connection will not be damaged when the entire section of the member yields.

3.Stability

During the construction and use phases, the stability of the structural components is guaranteed.

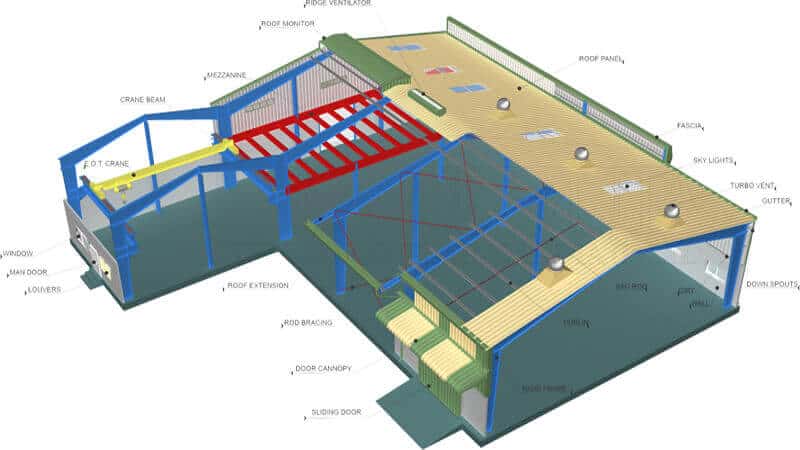

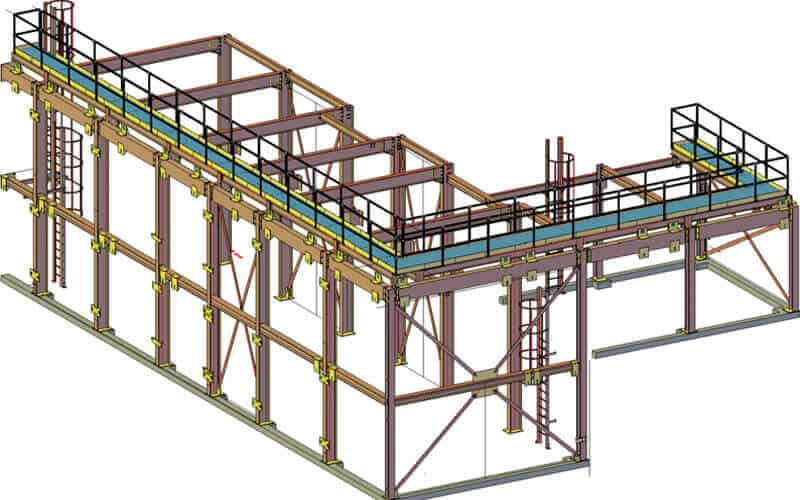

Multi-story Steel Structure Workshop

A multi-story Steel Structure workshop building is another form of an industrial building with excellent development prospects. Generally, it refers to the industrial factory building, workshop, warehouse, etc. Below ten stories and less than 20 meters in height, most of the modern multi-story steel structure workshop was constructed with the Portal Steel Frame Structure System.

Multi-story steel structure workshops are generally composed of columns, beams, floor structures, support structures, wall panels, or frames. The multi-story steel structure adopts a plane rigid floor to ensure the space’s overall rigidity and the area’s coordination. The transverse edge is a column-support system and uses a plane rigid floor. Multi-story steel structure workshops are also widely used in the design of workshops. It can take full advantage of the stiffness of beams and columns used in any situation in a standard factory building, but when the columns are rigidly connected to the beams, the bearing capacity of these columns becomes greater by bending the frame to resist horizontal and vertical loads.

When designing the layout, take note of the following technical points:

1. The multi-story Steel Structure Workshop Building generally adopts the frame structure system, also called a multi-story steel frame structure, composed of the column, beam, floor structure, bracing structure, wall panel, or wall frame.

2. The rigid plane floor should be adopted to ensure space integral rigidity and coordinate work. When the transverse frame is the column-bracing system, the space between columns is not more than 40m.

3. Reasonable arrangement of column distance and beam system, uniform LongitudinalLongitudinal and transverse stiffness, special force transmission, uniform type of members, simple joint structure, and easy construction.

4. The steel column and its bracing can change the cross-section along the vertical direction, but the sudden change of inter-story stiffness should prevent.

Features of multi-story steel structure workshop:

- The multi-story steel workshop has higher space utilization, strong bearing capacity, stable structure, and a beautiful appearance.

- The steel structure components are processed in the factory and have high reliability.

- The raw materials of the multi-story steel structure workshop have good shock and impact resistance.

- The steel structure workshop has lightweight and has a small footprint, all of which increase the actual usable area.

- The steel structure can be assembled quickly and accurately, shortening the construction period.

Advantages of multi-story steel structure workshop

The production of the multi-story steel structure workshop is carried out on different elevation floors, with a horizontal connection between each floor and a vertical connection. Therefore, in the design of the factory building, it is not only necessary to consider the reasonable connection between the sections on the same floor and to solve the vertical connection between floors and arrange the traffic in the vertical direction.

- Beautiful and practical: The lines of the multi-story steel structure building are simple and smooth, with a modern sense. Colored wall panels are available in various colors, while other materials can be used for the walls, allowing for greater flexibility.

- Simple construction and short construction period: All the components needed to build a multi-story steel structure building are prefabricated in the factory and only need to be simply assembled on the construction site, thus significantly shortening the construction period, a building of 6000 square meters, The basic installation can be completed in just 40 days.

- Reasonable cost: The multi-story steel structure building is light in weight so that the essential cost can be reduced, the construction speed is fast, and it can be completed and put into production as soon as possible, and the comprehensive economic benefit is much better than that of concrete structure buildings.

- Durable and easy to maintain: multi-story steel structure buildings can resist harsh weather and only need simple maintenance.

- Save land: The multi-story steel structure workshop has the characteristics of a small footprint and land saving. For example, a single-story factory building with a construction area of 10,000 m2 needs an area of 10,000 m2. If it is changed to a five-story multi-story factory building, its floor area is only 20,002 m2, which is more economical than a single-story factory building. Four-fifths of the land.

- Save investment: reduce the cost of civil construction. Since the multi-story workshop occupies less land, the amount of earthwork for the foundation is reduced, the roof area is reduced, and the cost of roof gutter, rainwater pipe, and outdoor drainage works is also reduced accordingly.

- Shorten the road and pipe network in the factory area: the multi-story factory building occupies less space, and the factory area is also reduced accordingly. The length of various process pipelines such as railways, highway transportation lines, and water and electricity in the factory area can be shortened, saving part of the investment.

Structural combination type of multi-story Steel Structure Workshop:

(1) Steel frame system:

Rigid-jointed frame in both vertical and horizontal directions is suitable for buildings with large column spacing but no bracing.

(2) column-bracing system:

Beam-to-column are hinged joints, and column-to-column bracing (lateral resistance members) is provided along with column height in both Longitudinal and transverse directions, saving the quantity of steel.

(3) frame-bracing system

Longitudinal column-bracing system; lateral steel frame system, on the one hand, to meet the functional requirements of the building, on the other hand, to simplify the design and construction, and reduce the amount of steel.

(4) frame-bracing composite system.

The floor forms of the multi-story Steel Structure workshop are galvanized metal bearing plate, steel frame beam and precast cement plate, steel frame beam and pattern steel plate, steel frame beam, and wood plate.