There are many ways to classify building steel structures. According to the structure type, they are portal frame, steel frame,…

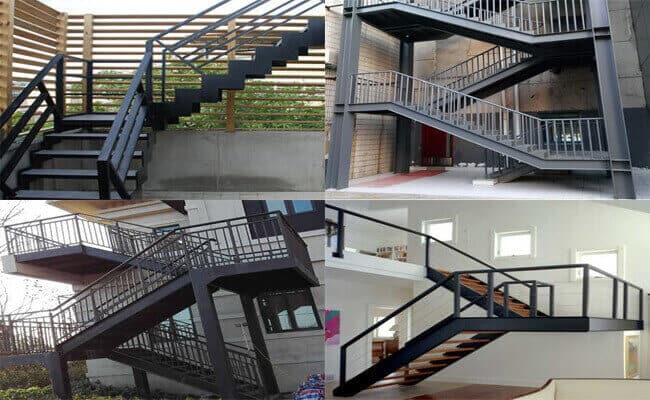

The steel structure stairs are simple in design, cost-saving, and easy to use. Steel structure stairs have become a new type of staircase building material and are widely used because of their small footprint, beautiful appearance, strong practical ability, and durability. When designing steel structure stairs, the structure’s safety should be the priority, and then the loading and unloading should be convenient. When constructing, pay attention not to step down before the stairs and pay attention to the height of the stairs and the distance between the railings.

Design elements of steel structure stairs

Safety: The safety of the stairs is the priority. The connection fastness of the various parts of the stairs, whether the design parameters of the stairs are safe, and the steel structure mezzanine all need to be carefully considered. The choice of steel is one of the essential factors affecting the safety of stairs. For general structure, use national standard Q235B grade steel or national standard Q345B grade steel. The steel has good weldability, is economical, has good cutting performance, and is easy to process. It is suitable for large and medium-sized structures or general steel structures. , And metal architectural modeling. It is not possible to replace ordinary steel below the national standard steel standard at will.

Easy to Disassembly: Stairs are bridges connecting the upper base space. Try to use splicing technology that can be easily disassembled to facilitate installation and disassembly.

Unique shape: Steel stairs have U-shaped corners, 90-degree turn right angles, S-shaped 360-degree spirals, and 180-degree spirals, with various shapes and intuitive lines.

Scientificity: The stairs are designed to operate the mechanics and ergonomics principles fully. By clarifying the mechanics of the stairs products when they are used, the ridge-locking structure method with separate bearing, dynamic force, and flexible support is designed.

People-oriented: The design of the fence emerges this concept. The 8-12mm guardrail spacing is designed in strict accordance with the international safety standards to absolutely guarantee the safety of the use of the elderly and children.

Application of steel structure stairs

Steel structure stairs are mostly used in industrial workshops as fire-fighting backup ladders, and the floor height is not limited. Steel structure stairs have the advantages of fast construction, durability, high safety and low cost. The outdoor fire building is basically in the form of steel structure. The styles of steel structure stairs include Z-shaped, flat-shaped, arc-shaped, etc. The specific style is more suitable depending on the place of use. For example, most outdoor ladders are Z-shaped, and industrial buildings Both the indoor Z-shaped and the in-line shape are suitable, depending on the floor height. As for the arc type, it is mostly used in civil or commercial buildings. H-beams or I-beams are mostly used for the production of steel structure stairs in Shanghai, and channel steel is also used. Steps are made of patterned steel plates. Due to the long-term exposure to weathering erosion such as sun and rain, all components must be sprayed with anti-corrosion paint or galvanized.

For some duplex buildings or villas, steel structure stairs are used to connect the upper and lower floors, which play the role of connection. Different types of steel components can also be built due to the plasticity of steel in building some high-demand shapes, and secondly, they will not be broken or the bending degree will not meet the requirements due to processing.

Stair style:

There are various styles and shapes of steel structure stairs. There are many types of stairs for people to choose from, such as: curved stairs, U-shaped stairs, spiral stairs, semi-circular stairs, outdoor steel frame stairs, retractable attic stairs, keel stairs, single keel stairs Stairs etc. The use of steel structure to build stairs is safe, simple and diverse, and can meet the needs of various spaces. The color and material can be selected according to the preferences of different customers.

foot

Material:

When building a steel structure staircase, attention should be paid to the selection of materials, the fixation of embedded parts, the quality of welding connections, and rust removal and anti-corrosion. The steel material affects the safety of the structure. The specifications, models and thicknesses of the steel vary. There may be more than a dozen different qualities of steel for one type of steel. When selecting specific steels, it is necessary to select steels with appropriate design requirements and quality requirements. The installation of the embedded parts is a key issue affecting the structural connection and load-bearing. If the fixed point of the embedded parts is a concrete structure, the expansion screws can be well “eat and live”. Pre-embedded parts allow the entire structure to withstand the expansion screws well.

The second is the selection of suitable welding methods and welding materials. The selection of professional welders for welding can solve many construction details and ensure the quality of structural welding. Rust removal and anti-corrosion, steel structure stairs generally need to be treated with anti-corrosion because of the low anti-corrosion performance of the components. The steel components will also be treated with anti-corrosion during the production. , strengthen the anti-corrosion performance of the components, and secondly, if there is rust on the steel components, it must be clear and clean before painting, and the surface roughness of the rust-removed steel components must meet the actual requirements.

The steel structure stairs and the corners should be connected with channel steel. The connection, width and height of the pedals should conform to people’s daily walking habits. When the number of steps reaches a certain level, the platform should be designed, and the platform can also be erected according to the actual type of the stairs. . The steel structure stair construction and the original building structure are a process of mutual force, and the original building structure cannot be damaged at will, to ensure that the force of the two structures is consistent and the safety is guaranteed.

Precautions for indoor staircase construction

- Avoid the illusion when going up and down; the height of the stairs’ first and last steps should be the same as other steps.

- The height from the highest step to the ceiling of the stairs must have a clearance of more than two meters, and the minimum is not less than 1.8 meters. Otherwise, there will be a sense of oppression.

- The distance between the railings: The distance between the centers of the two railings should be 8 cm, not more than 12.5 cm, to prevent children from sticking their heads out of the gap.

- Railing height: The height is 85-90 cm to the waist position, and the handrail diameter is 55 mm.

- Step height and depth: The step height should be 15~18 cm, and the step surface depth should be 22~27 cm. The number of steps is about 15 steps. If it is too high, it may be necessary to set up a landing.

- Stair width: when one side is in the air, the clear width is not less than 75 cm; when there are walls on both sides, the clear width is not less than 90 cm.

- Safety: The parts of the stairs should be smooth and round, without protruding or sharp parts. For families with children and older people, the slope of the stairs should be gentle, and the rotation angle should not be too large; anti-skid measures should be taken for the stair treads, such as anti-slip strips, anti-slip mats, and anti-slip grooves.

- Stairway lighting: Too dark lights are not conducive to walking safety, and too bright lights are prone to glare. Therefore, the staircase light should be soft and clear.

- Staircase style: The design of the stairs should be consistent with the decoration style.

- Stair noise problem: It is related to the connection of the various parts of the pedal, and it should not produce excessive noise during use so as not to affect the rest of the family members.

Steel structure stairs can provide more modeling options, and the surface treatment process of steel stairs is diverse. It can be fully automatic electrostatic powder spraying or fully galvanized or fully painted, which is beautiful in appearance and durable. Suitable for most occasions, such as indoor or outdoor use. It can reflect the modernist steel structure architectural art. At present, it has been widely used in various large-scale factories, stadiums, high-rise buildings, and other fields.