The service life of steel structure buildings is more than 50 years. The roof and wall panels of prefabricated steel…

The workshop is a building used for industrial production, and it can also store raw materials and finished products. At present, more and more workshops are designed and constructed with steel structures. The prefabricated steel workshop can be customized, and the structure can be designed according to different production processes.

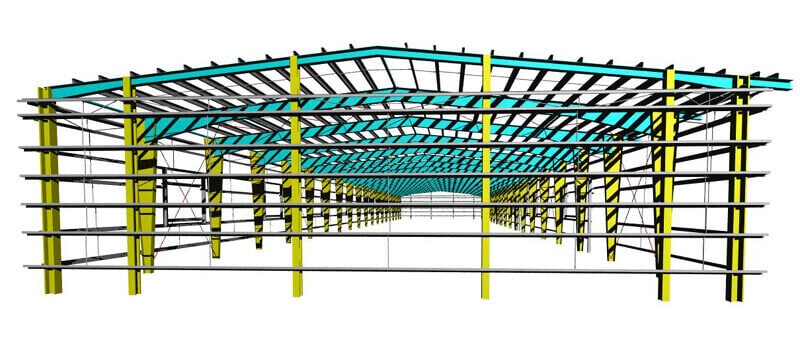

Composition of prefabricated steel workshop:

Anchor bolt: used to stabilize the primary structure. The anchor bolt connects the steel column to the foundation.

Primary structure: steel column, steel beam, crane beam. The primary structure belongs to the workshop’s load-bearing framework and plays an important role in the building’s safety. The prefabricated steel workshop design must first ensure that the primary structure can pass the check under the external action force to ensure its safety and economy.

Secondary structure: bracing, tie beam. The secondary structure is connected with the primary structure to form a whole building structure. The secondary structure is mainly used to stabilize the primary structure and transfer the external forces to the foundation.

Purlins and wall girts: Purlins and wall girts support the roof and wall panels and transmit loads to the primary structure. It is fixed on the main structure and is integrated with the bracing to ensure the workshop’s space rigidity and transmit horizontal loads.

Performance of the Prefabricated Steel Workshop

Shock resistance

The advantages of the seismic performance of the structural workshop are first reflected in the materials. The toughness of the steel components is excellent, the force is uniform, and there will be no sudden fracture. Moreover, the steel structure has strong adaptability to the environment, and wind and earthquake resistance performance are better.

The main load-bearing material of traditional factory buildings is masonry, brittle material with relatively poor seismic performance. Instead, the steel structure workshop is built from light I-beam, cold-formed thin-walled steel, round steel, small-angle steel, profiled steel plate, sandwich panel, and other materials, which fundamentally guarantees the seismic advantages the steel structure workshop foundation. In addition, the structural modulus of steel structures is also the simplest and most industrialized in the world.

Wind resistance

The steel structure is lightweight, has high strength, good overall rigidity, and strong deformability. The weight of the building is only one-fifth of the brick-concrete structure, and it can withstand a hurricane of 70 meters per second so that life and property can be effectively protected.

Heat preservation

The heat preservation and heat insulation materials used are mainly glass fiber cotton, which has good heat preservation and heat insulation. In addition, the use of thermal insulation boards on the outer wall effectively avoids the “cold bridge” phenomenon and achieves a better thermal insulation effect. The thermal resistance of R15 insulation wool with a thickness of about 100mm can be equivalent to that of a brick wall with a 1m.

Comfortable

The roof has a ventilation function, forming a flowing air space above the house to ensure the ventilation and heat dissipation requirements inside the roof.

Design case of prefabricated steel workshop:

Building size:

24.5m (width) x 115m (length) x 7.5m (height)

Structure: single span, double slope, column distance: 6m.

Enclosure structure: 0.6mm color steel plate

The project is located in Guam, USA, where wind speeds and earthquakes are relatively high. To ensure the structural strength during the design, we increased the cross-section of the steel column and the steel beam, and the distance of the purlins was shortened from the conventional 1.5 meters to 1 meter, which increased the number of purlins.

External forces have an important influence on the price of steel structure workshop. Prefabricated steel structure workshop buildings can resist external loads only by increasing the section of steel components. While increasing the steel components section, the amount of steel used in the workshop will increase so that the price will be slightly higher than that of the ordinary workshop.

The Benefits

The prefabricated steel structure workshop has the advantages of a lightweight, good seismic and impact resistance, and good fire resistance. Therefore, it is widely used in many plant designs. The form of steel structure has significant advantages in the structural design of industrial buildings.

First of all, steel structure construction has the characteristics of green and environmental protection. It not only uses environmentally friendly materials but also generates very little construction waste during construction. It can also be recycled with high energy efficiency. It is environmentally friendly and convenient. It is a building structure that conforms to the concept of environmental protection.

Secondly, the construction operation is straightforward and flexible. In constructing traditional reinforced concrete structures, the construction period is long, and the construction technology is often required, making the construction difficult. In installing the prefabricated steel structure workshop building, the components are optimized during the production process, convenient for assembly, and greatly improving efficiency.