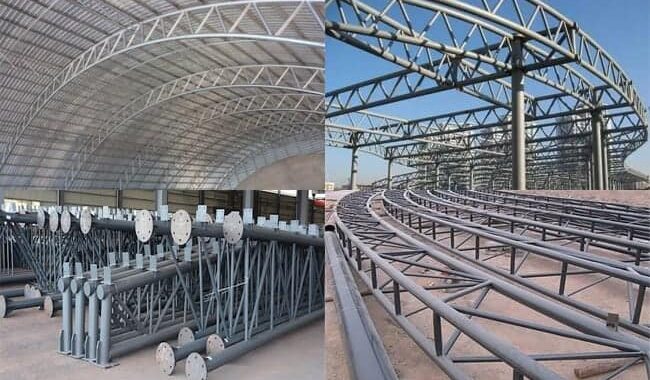

There are many ways to classify building steel structures. According to the structure type, they are portal frame, steel frame,…

Havit Steel has designed and manufactured 17 units of steel structure warehouse buildings in Hawaii, USA, all of which are in accordance with the design standards of American Metal Buildings. We have provided a comprehensive set of design drawings, calculation reports, and installation drawings for each unit.

General of Design of American Metal Buildings

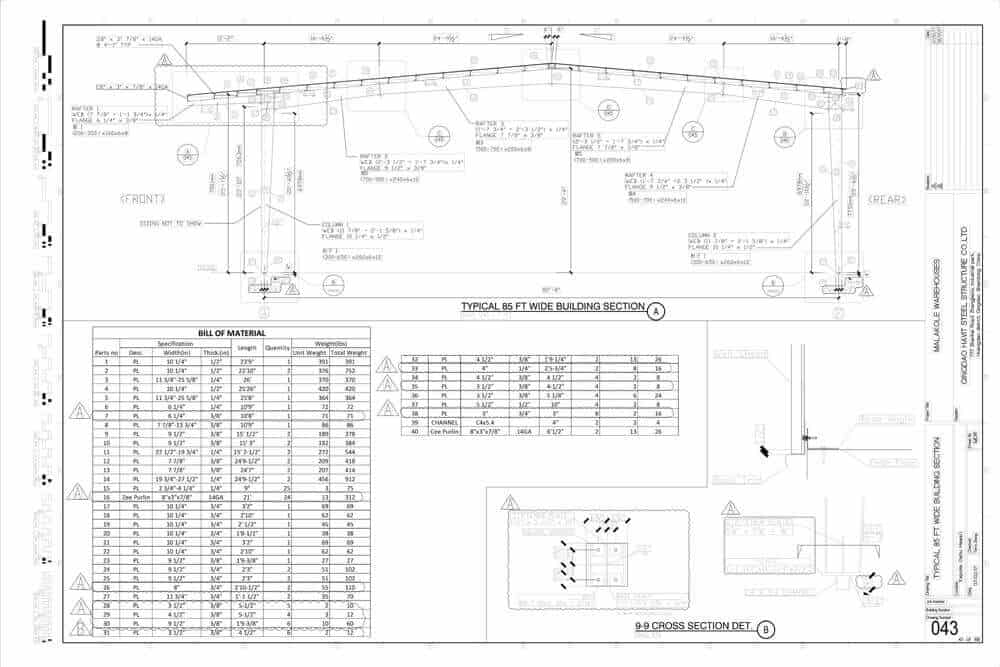

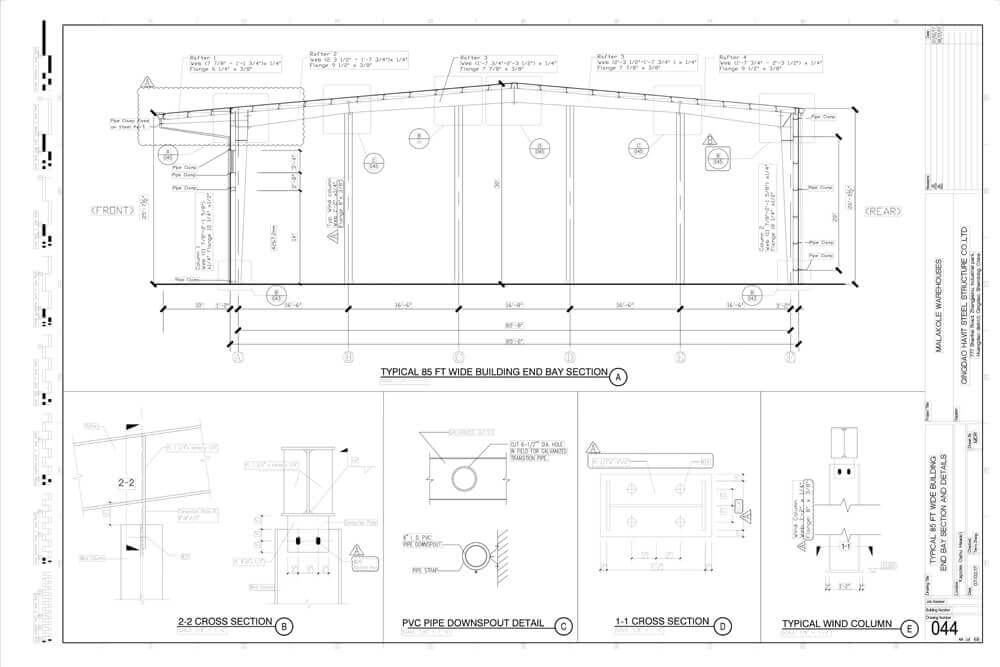

- The design is for Malakole Warehouses, Kapolei, Oahu, Hawaii

- Discrepancies. Metal Building Supplier shall verify all dimensions and conditions and shall report any discrepancies in writing to the owner before commencing work or ordering materials.

- All materials and quality shall conform to the requirements of the local building code in addition to the Codes cited.

- Details shown on the drawings shall be typical for all similar conditions.

- Modify details for particular requirements as directed by the owner.

- Metal Building Supplier to include in its bid or proposal, any costs to change the structural supports to accommodate actual equipment or item used.

- Roof Slope 1:12

Design Loads

(1)Live Load: Roof 20psf(Reducible Per IBC 1607.9)

The reduction cannot exceed 50 percent for elements that support loads of a single floor.

20 psf of roof live load may not reduce to less than 12 psf

(2)Additional Superimposed Dead Load

Roofing 2psf

Mechanical/Electrical/Ceiling Hung System 5psf

Collateral Loads 5psf

(3)Lateral Load

Wind Load: Design Wind Speed 105mph, Exposure B, Enclosed Building, Importance Factor

I=1.0, Internal pressure coefficient= /- 0.18

Seismic Load: Ss=0.546g, S1=0.152g, Sds=0.496g, Sd1=0.222g, Importance Factor=1.0, Site

Classification: C, Seismic Design Category: C, Cs=0.15, R=3.25, Seismic force-resisting system:

Ordinary steel concentric braced frame

Building Code for Design of American Metal Buildings

Load Code for the Design of Building Structures (GB50009-2001)

Code for Seismic Design of Building (GB50011-2010)

Code for Design of Steel Structures (GB 50017-2003)

Technical Specification for Steel Structure of Light Building with Gabled Frames (CECS 102-2002)

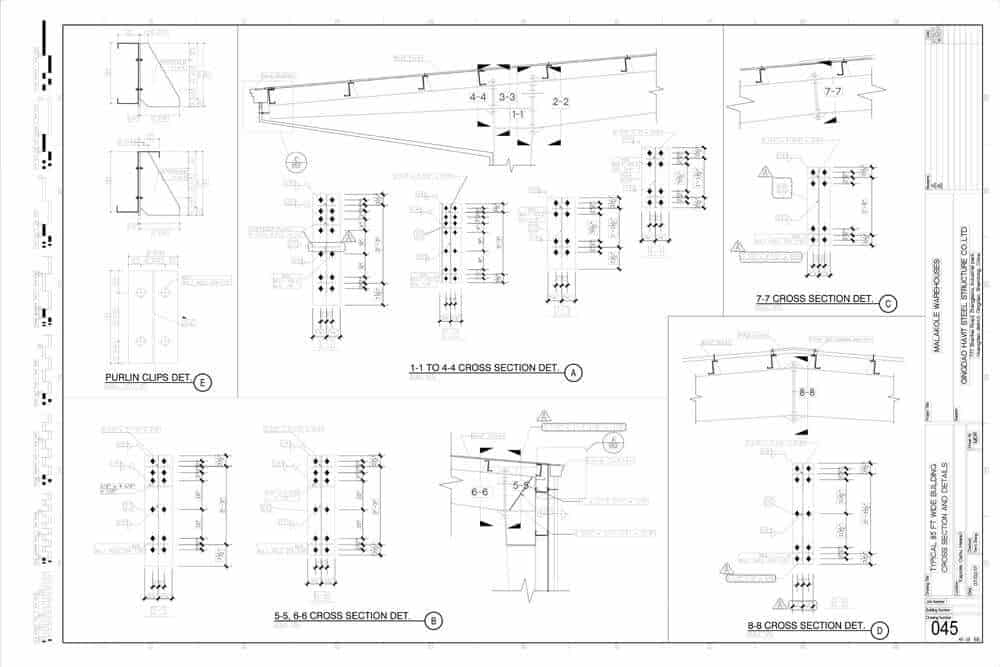

Pre-engineered metal building and building cladding system for the above-referenced job per the plan and specification as follows:

Main Structure

Steel Column/Steel Beam: GB/T1591 – Q345B

Secondary Structure

Bracing/Purlin/Tie Beam/Steel Rod: GB/T700 – Q235B

Wall and Roof Panel

GB50003-2011

Trim/Gutter/Flashing

GB50003-2011

Roof Panel: Corrugated Steel Sheet YX25-205-820, 24Ga

Wall Panel: Corrugated Steel Sheet YX25-205-900, 24Ga

Translucent Panel: PVC Sheet YX25-205-900, 0.04” thick.

Trim, Gutter, and Flashing: Galvanized 0.02” thick.

Down Pipe: PVC

Welding

- All welding shall follow the provisions of the American Welding Society Code AWS-D101, latest edition.

- All welding shall be done by certified welders holding current and valid AWS certificates and having current experience in the type of weld called for.

- All welding shall be done by the shielded arc process using approved electrodes per AWS specifications E70xx (low hydrogen electrodes).

- All welds shall have a weld-controlled sequence and technique to minimize shrinkage stresses and distortion.

- All electrode filler materials shall be a minimum of E70xx.

- Welding of sheet metal shall be following the 2006 IBS section 2204.1

- Identify special procedures for field welding of structural steel elements which have been hot-dip galvanized after fabrication. Procedures shall ensure the weld’s quality by removing zinc materials during welding procedures.

- All welding done after galvanization shall be protected with two coats of “galvalloy” or approved equal.